Understanding the default configuration concept for constraint-based products

Introduction

The default configuration concept enables users to start the product configuration process when the main product master data are available within a legal entity. You can learn more of the details of this concept in this post.

The default configuration concept

You must use the configuration technology Constraint-based when you configure product masters and the product masters must be configured with only one active product dimension, the Configuration dimension. We refer to the products masters as constraint-based products throughout this post.

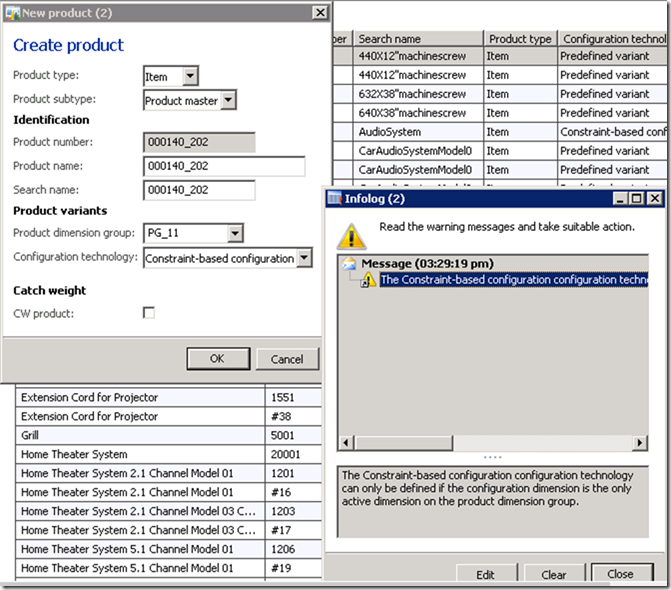

To create a constraint-based product you must specify a valid product dimensions group which complies with this requirement.

Figure 1 Error message when the wrong dimension group is selected

You use the Configuration dimension to capture the final product configuration of a certain product model. The product model is represented in the system as a new product variant with a specific configuration dimension value. This is how Dynamics AX distinguishes between different results of the final product configuration. This allows you to complete a lot of tasks, such as:

- Record and view on-hand inventory for individual configurations.

- Run master planning against specific customer requirements (and across different legal entities).

- Reuse existing product definitions in order to create products that are identical to existing products. You can also apply existing product definitions across legal entities.

Once you have released a constraint-based product to a legal entity, you can kick off a product configuration process from the following source document lines:

- Sales order line

- Sales quotation line

- Project order line

- Production order line

- Purchase order line

The product dimension Configuration must have a value before you can start the product configuration process for a selected constraint-based product on an order line. Also, all active product dimensions must be specified before you can save an order line. These requirements are based on a series of technical solutions which are consistent with the experience that many users have from the Product Builder functionality.

Note - This is always the case for stocked products .For non-stocked products, you can specify a product category instead of defining the particular SKU.

The default product configuration concept is dedicated to solve the above described issue. It enables end users to proceed with the product configuration as soon as the product has been released to the legal entity.

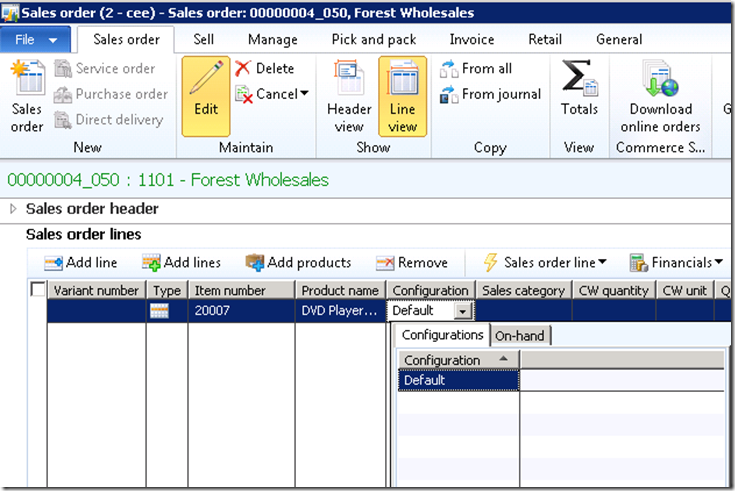

Figure 2 The Default configuration is just there, after the product release

When a constraint-based product is released to a legal entity, the system automatically creates and releases a default product variant with the configuration value Default. The Default parameter is derived from the Default configuration ID field on the Constraint-Based product configuration models tab in the Product information management parameters form. This form is located under Product information management > Setup. The Default configuration ID value is set automatically during system installation. It references the SYS Label @SYS331038, but you can always change the value.

Figure 3 Product Parameters form

The process to create and release the default product variant is completely transparent and once the Default configuration ID parameter is set, no further action is required. If the product is released to multiple legal entities, the same default product variant will automatically be released to all of those legal entities.

Once the default product variant is released to the legal entity, the system will also update the default product variant fields on the released product. The default configuration dimension value is provided when you enter the item number on the order line. Any end user can change this setup in order to, for example, always have a basic configuration of a specific product suggested on all order lines

Figure 4 The default product variant dimensions are set to match the Default Configuration ID

Summary

The default configuration concept makes it possible to start the product configuration process at the point where the main product master data are available within a given legal entity. In order words, it facilitates the first step in the overall process of configuring an order line and it goes without saying that the first step is a prerequisite to move on in the process. Thanks for reading.

Comments

- Anonymous

August 05, 2013

The comment has been removed - Anonymous

May 22, 2014

I am looking for a way to copy a defined configuration from one item to another. The purpose is to 'rev' an existing default configuration. So ItemA has a configuration ID that includes many variables set using a fairly generic product configurator model. ItemB will be very similar to A with a few changes. It would be brilliant, in a similar manner to BOM copy, to carry the config over, tweak a few things, and then set this new config ID as the default for ItemB. - Anonymous

May 22, 2014

The comment has been removed - Anonymous

May 23, 2014

Hi Sverre,I was not actually referring to the 'default'/ dummy configuration. What we are looking for is a way to carry over a configuration created for one item to another item so that the attribute choices and other values selected/ entered are in place and the user does not have to start from scratch, nor does the client have to create many product configurator models with defaults set on the attributes. - Anonymous

May 26, 2014

The comment has been removed