Round up work for raw material picking to match the handling unit

This blog post describes the functionality of a new hofix that is released in the Microsoft Knowledge base (KB) in article 3120530.

After installing this hotfix it is now possible to configure the location directive for raw material picking, so work can be rounded up to the nearest handling unit in which the material is picked for production.

Consider following scenario:

A food manufacturer uses a special flour for making a powdered soup mix. The flour is stored on pallets in 50 lb bags in the bulk warehouse. For making 4,475 lb of the powdered soup mix 510.15 lb of flour is needed. This corresponds to 10 x 50 lb bags + 10.15 lb. As the material is always picked in bags (the handling unit), the warehouse worker will in this case pick 11 bags. After the 11 bags are moved to the production floor, the bags are broken and 510.15 lb is weighed off and applied to the production process. The remaining quantity from the last bag will remain on the input location and either be consumed by the next batch order or moved back to the warehouse.

Before the release of this hotfix it was possible to set up in which handling unit the material should be picked, but it was not possible to round-up the quantity to the nearest handling unit. In the above example, work for raw material picking would have been created for 10 x 50 lb bags and 10 lb i.e. for the same work the material would be picked in two different units. This scenario is still supported, and is relevant for some customers who wants to weigh of the material at the warehouse location (in this case the remaining 10.15 lb).

Let us take a closer look at how the mechanism to round up work to the nearest handling unit has been enabled.

Setting up the location directive for raw material picking

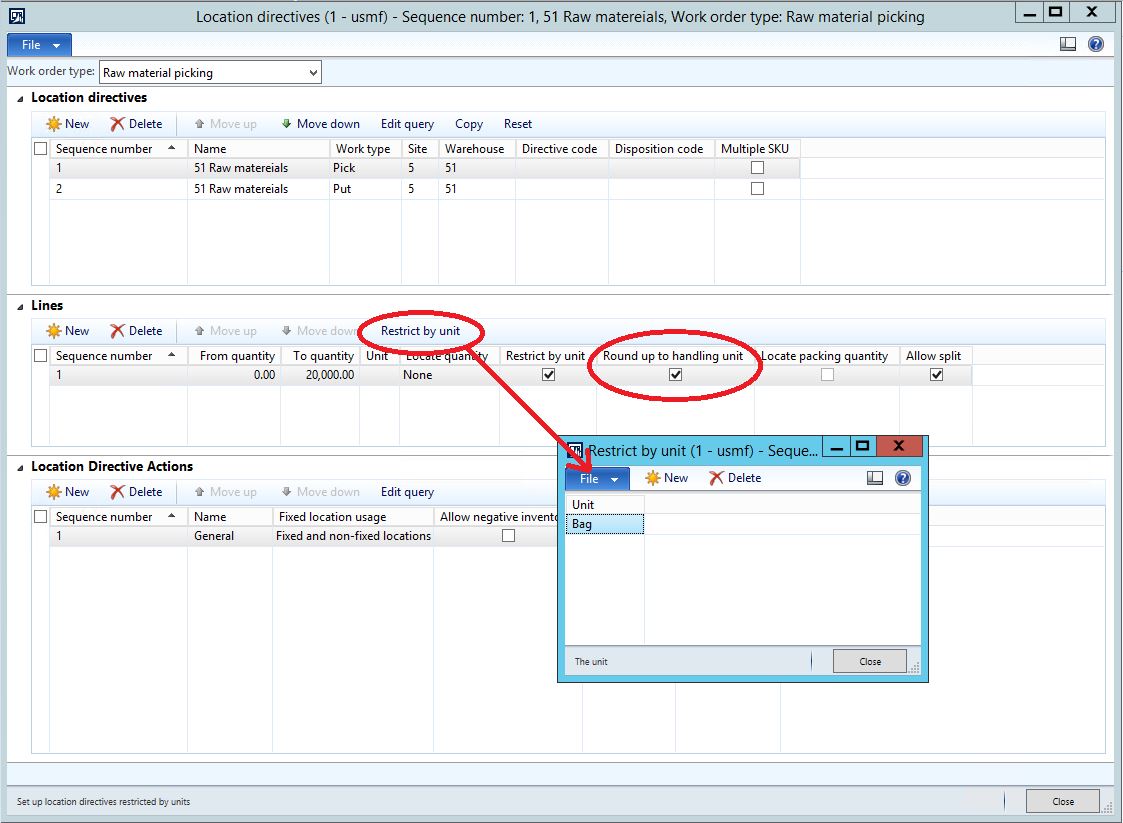

In the location directive for raw material picking a new field Round up to handling unit has been introduced:

This field works together with the field Restrict by unit. In this example the location directive is set up to pick in the unit of Bag, and selecting Round up to handling unit indicates that the work generated out of the directive should be rounded up to a multiple of one handling unit.

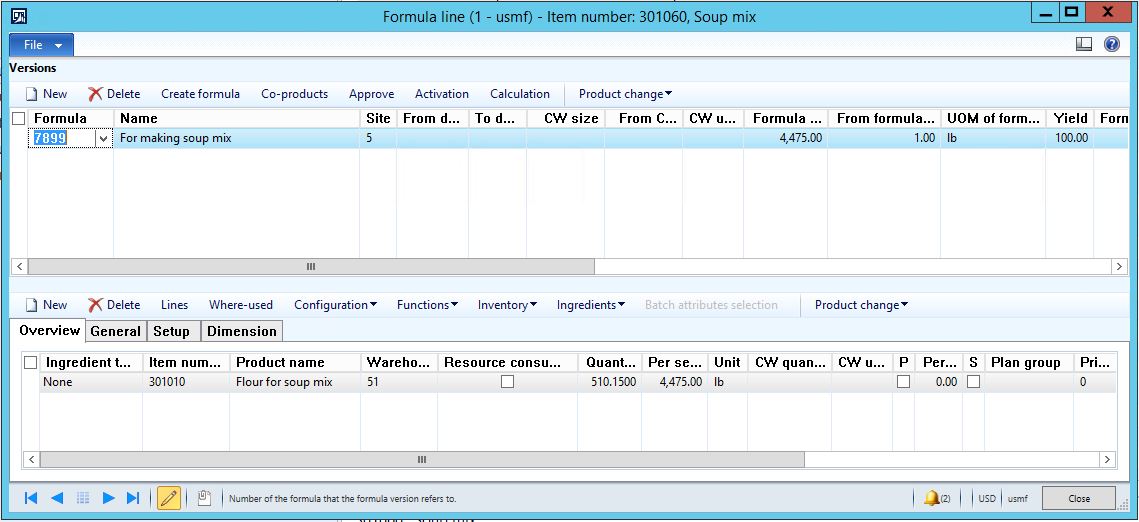

Setting up formula and ingredient

In this example a formula version for making the soup mix is set up with a batch size of 4475 lb, consuming 510.15 lb of Flour

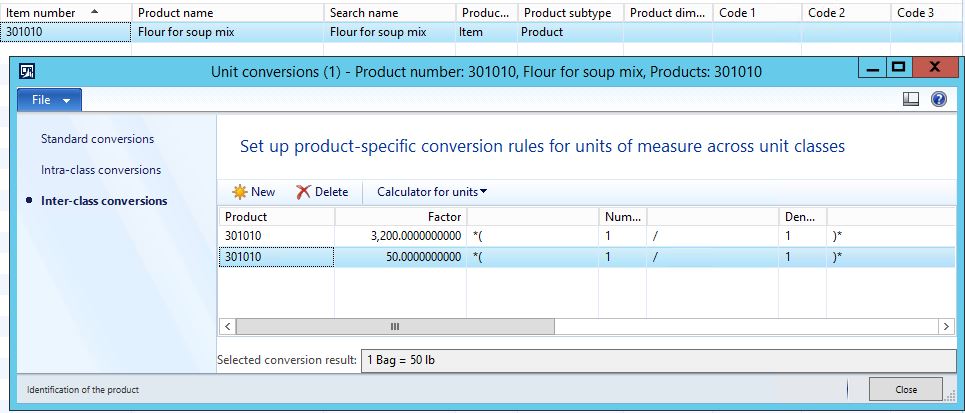

A unit conversion has been set up for the Flour ingredient between the unit’s bag and lb.

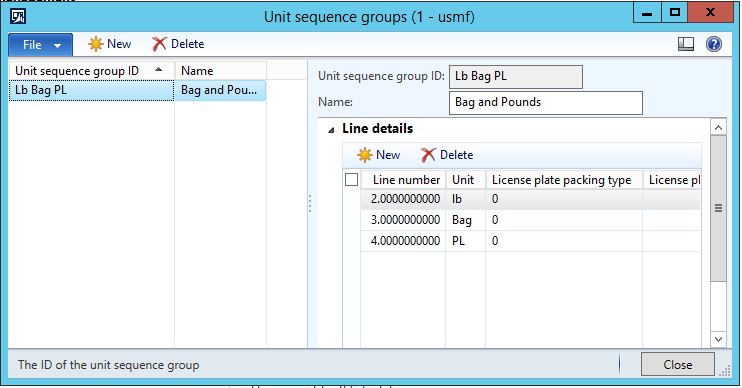

The following Unit sequence group is used for the item. The inventory unit must be the first unit in the sequence group, in this case lb.

Releasing work for raw material picking

A batch order is now created and released for the batch size of 4475 and warehouse work for raw material picking is generated.

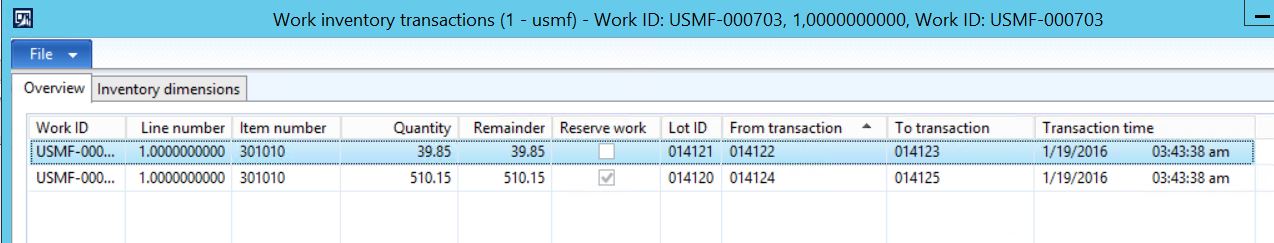

As it can be seen from the work details work is in this case rounded up to 11 bags. The batch order is still only reserving the required quantity 510.15 which can be seen from the work transactions form that can be opened from the work details form:

If the rounding option had not been used on the location directive, then the resulting work would have looked like this:

In this case the warehouse worker would have to pick 10 bags and weigh of the remaining 10.15 lb on a warehouse location. This process is enabled in the location directive by adding a line that is not restricted by unit. This line will make work for the remaining quantity.