Practical experiences on implementing the (WHS) warehouse module – Packing

In continuation on our experiences with implementing WHS Warehouse management I will go into the creation of works and packing the items into containers.

Once we have a shipment with the correct sales order lines in it, this shipment will hit the wave template and get processed into work. An option when creating works is using the “Work breaks” on the work template. The work breaks is a consolidation/break mechanism based on a set of temporary work transactions, personally I read them as the predecessors to what will be the Work pick lines. Note that the creation and splitting/grouping of work lines are done within the scope of one Wave processing of the shipment within one wave, meaning that to consolidate two sales orders/sales order lines they have to be a part of shipments within one wave.

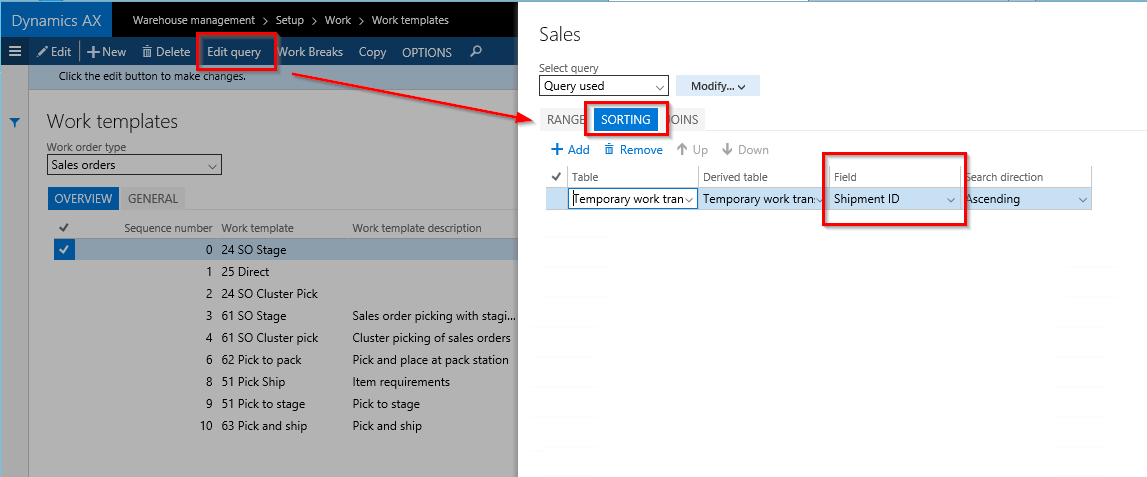

Using the Work breaks is done first by adding a range on the sorting tab on the Edit query:

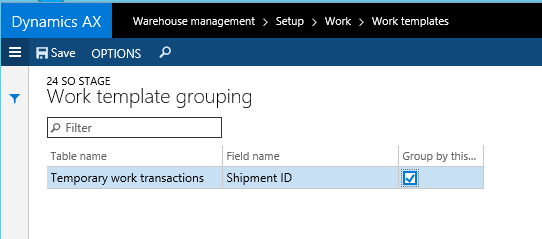

And secondly by choosing yes to “Group by this field” in the Work breaks form called from the Work template form.

In the above I have done a grievous error in not having the sort code field on the sorting tab, my warehouse workers are going to be rather tired from walking randomly all over the warehouse without a guided picking route. Just remember not to have group on the sort field or you will have a work per sort code..

The above setup (plus sort code) worked for us because we used the pack functionality to add the items into containers and the Pack/Manual containers functionality handles multiple shipments in one work.. in a manner that did not give a satisfying user experience.

The Packing functionality.

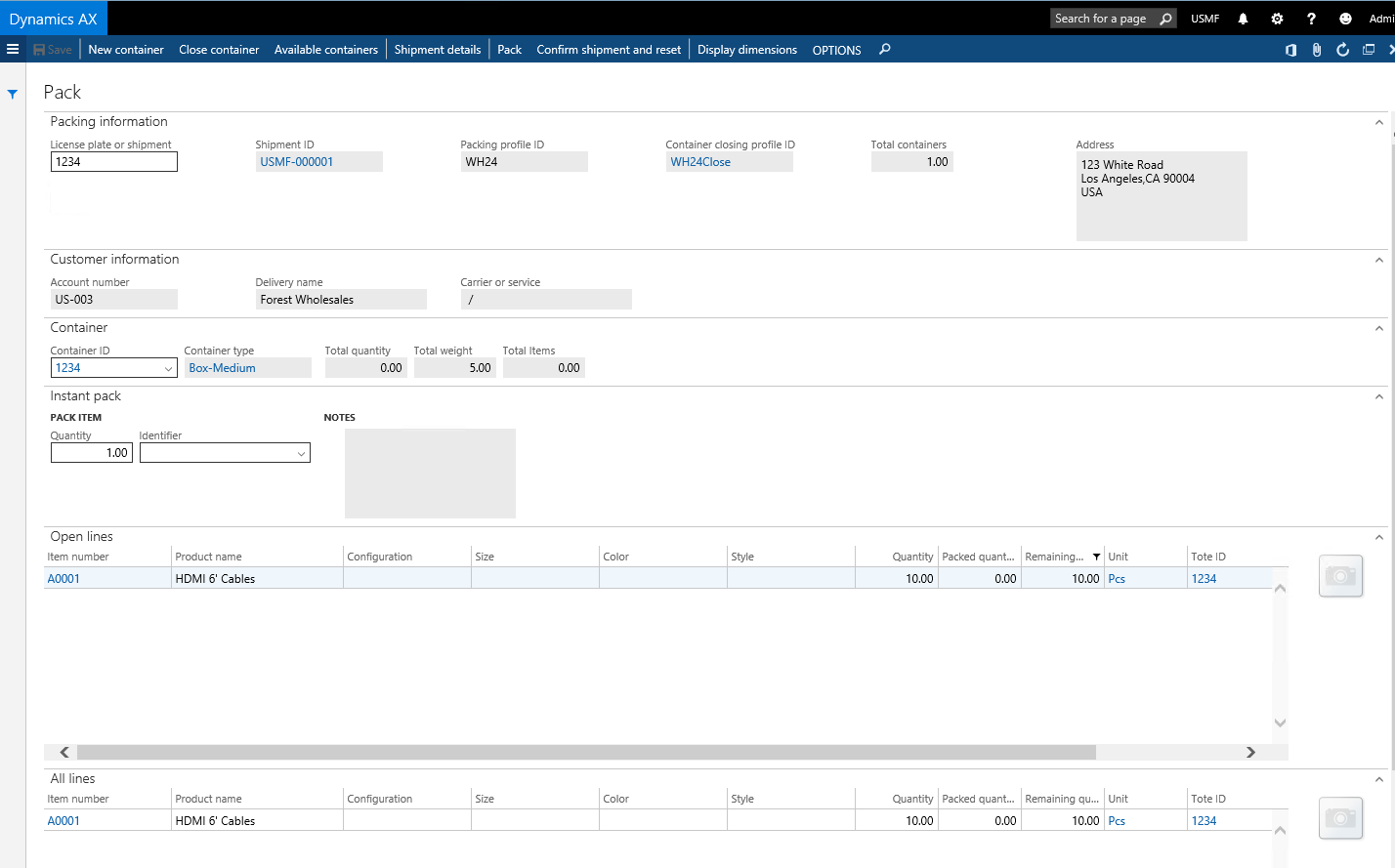

The packing functionality requires that an area of the warehouse has been setup as the pack area – a specified location profile in the parameters. Secondly a Packing profile and a container closing profile must be created for each warehouse. To ease the daily opening it is possible to reference a user login with the packing profile and container closing profile although my experience was shared logins for a diverse group of permanent and temporary employees and it had no effect that the employee typed his/her own name when opening the form, data was still stored with the user credentials from Windows.

The notes comes from the attached notes to the work which can be inherited down from the sales order with the correct parameter setting under accounts receivable and warehouse management.

The most typical personalization was adding the shipment address to the form (Here added in the upper right hand corner), this was also done because with an added EDI integration to third party transport vendors it was left to the packing user to make a validation of the automatically suggested mode of delivery (carrier and service).

In the above I have identified the license plate (1234) that the picker used. We experimented with different scenarios in regards to for example use the early tote reuse (a fixed label on picking trays/carts/pallets) and ended up that correctly identifying a pick without printing out works papers required a roll of “license plates” that we later consumed as container IDs during the packing process.

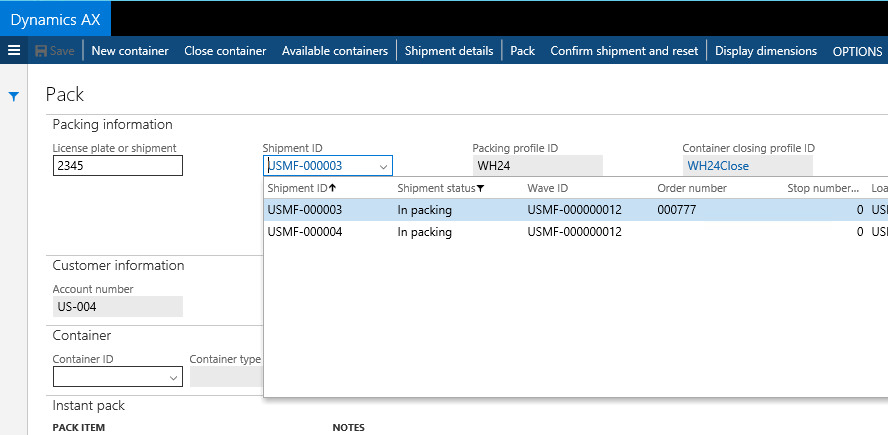

Note that when scanning a target license plate that represents a work spanning more than one shipment the following will happen:

The Shipment ID is enabled for editing and the user can pick which shipment is currently being packed. The above is an example where I have defined the work template breaks as the account number or in other words if the same customer has created two sales orders and each sales order has been released at different times (actually the above is three sales orders on the same customer – two of them were released at the same and ended up in one shipment). The two shipments have then “met” each other in the wave and has been processed together creating one work.

From a packing perspective the above has to be handled carefully. For one thing containers are related to shipments, so the above scenario has to result in two containers. Secondly if the items that has been picked are mixed together a likely scenario is that the user scans an item that is not in the currently active shipment giving the user an error or the risk of an over-delivery. For us the end result was actively avoiding the double shipment scenario.

In terms of modification we went with additional actions in regards to changing mode of delivery and some additional insight into the state of the current work. The EDI to the carriers were however by far the most challenging. Direct UPS integration requires a solid amount of care, attention to detail and data validation.