What's new in Microsoft Dynamics AX 2012 R2 – Potency management

With this blog entry, I would like you to familiarize you with the concepts that we have introduced in Microsoft Dynamics AX 2012 R2 to support potency management.

Potency management lets users define products as having a concentration of an active ingredient. The concentration of active ingredient can be used to affect the amount of material that is required in production or the amount that should be paid to a vendor based on the

concentration level.

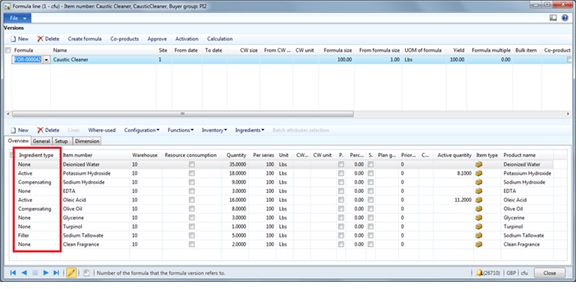

Process industries often have formulas that contain one or more active ingredients. For each active ingredient there may be one or more compensating ingredients. These compensating ingredients for a single active ingredient may have different effects based on the difference in the concentration level of the reserved inventory batch and the standard level of concentration for that particular active ingredient. In some cases, the requirement of compensating ingredient may increase to offset the increase in the concentration level of the active ingredient. In other cases, the requirement of compensating ingredient may decrease to offset the increase in the concentration level of the active ingredient. These are known as complimentary and opposing effects.

A complimentary effect occurs when the concentration level of the reserved batch for the active ingredient increases and therefore, less of the active ingredient is required and less of the compensating ingredient is required. A complimentary effect

also occurs when the concentration level of the reserved batch for the active ingredient decreases, and more of the compensating ingredient is required. In ice cream manufacturing for example, a formula for ice cream may contain milk that has a potency of 2% milk fat as an active ingredient, and milk powder as a compensating ingredient. If milk that has 4% milk fat is used for that production batch instead, then less milk powder, which compensates for the milk fat, is required.

An opposing effect occurs when the concentration level of the reserved batch for the active ingredient increases, and therefore more of the active ingredient is required and more of the compensating ingredient is required. An opposing effect also occurs when the concentration level of the reserved batch for the active ingredient decreases and less of the compensating ingredient is required. In food production for example, a formula for potato chips may contain potatoes that have a certain level of moisture, as the active ingredient. The compensating ingredient is the oil that is used to fry the potato chips. When the moisture content in the potato chips rises, then more oil is required to boil off the excess moisture. If the potatoes are drier, then less oil is needed.

There can be one or more formula ingredients that are configured as filler ingredients. Filler ingredients are used to fill up or ”top off” the batch quantity to achieve a required amount. Due to the nature of active ingredients and the required amount of compensating ingredients that result from the principle factor, the total amount of the active and compensating ingredients may be less than the estimated quantity totals. When this situation occurs, an adjustment is made to the quantities of filler ingredients to achieve the required quantity of the formula item. When more than one filler ingredient exists in the formula, then the adjustment amount is applied to the filler ingredients based on their relationship to each other.

Comments

- Anonymous

May 14, 2013

Even partner source upgraded Process manufacturing document "80309A_AX2012R2_ENUS_PMI.pdf" has no detailed description about "Ingredient Type" property, and how to effect formula. Can we take this is a microsoft documentation quality ? - Anonymous

May 26, 2013

There is a new blog that will give you more information about the use of Ingredient types in production:blogs.msdn.com/.../use-of-ingredient-types-for-batch-balancing-in-production.aspx