Setting up the production input location

This new functionality is available with KB 2995227 and will be included in Microsoft Dynamics AX2012 R3 CU8. To find the HF you can use LCS Issue Search.

What's new?

To support an efficient process for raw material picking in production, it is now possible to split warehouse work for raw material picking per route operation. As an example, this is useful in a so called bulk / pack production scenario. In this scenario there could be one operation for making the bulk material and one operation for bottling and packing. These two operations are both consuming materials, but will be carried out in different physical locations, maybe even different buildings. Splitting the work per operation will, in this case, secure a process where the warehouse worker is directed, by warehouse work, to deliver the picked materials to the exact locations, where the materials are consumed. This blog will explain how this is enabled by using the official demo data released for Microsoft Dynamics AX 2012 R3 CU8 Virtual Machine (VM).

The illustration below shows the Pellets production from the USPI Company:

The item numbers for the ingredients (or raw materials) as MW4004 - Polypropylene and MW4005 - Rubber are pre-fixed with MW and the four end items are pre-fixed with PW. PW4000 - Pellets is the formula item, and PW4001 – Chips and PW4002 - Blocks are co-products. PW4003 - Slag is a by-product

As it can be seen from the illustration, ingredients from the pellets production are consumed at two different operations. Let us see how work is now split per operation when releasing a batch order for the Pellets formula. First we create a batch order for Pellets and perform the following steps Estimate, Schedule and Release. In the Release step warehouse work is created:

In the work details form it can be seen that two warehouse works has been created in the release step. The first work is for allocating materials to the extruder operation, which is the first operation in the route. The materials are allocated to the production input location: EXT:

The next illustration shows the work details for the second work for the order. This work is for allocating materials to the Mixer operation. The materials are allocated to a production input location: MIX

Let us take a closer look how to enable this feature. First we need to set up the production input locations that will be applicable for the route operations. The Pellets formula has a production route with four operations

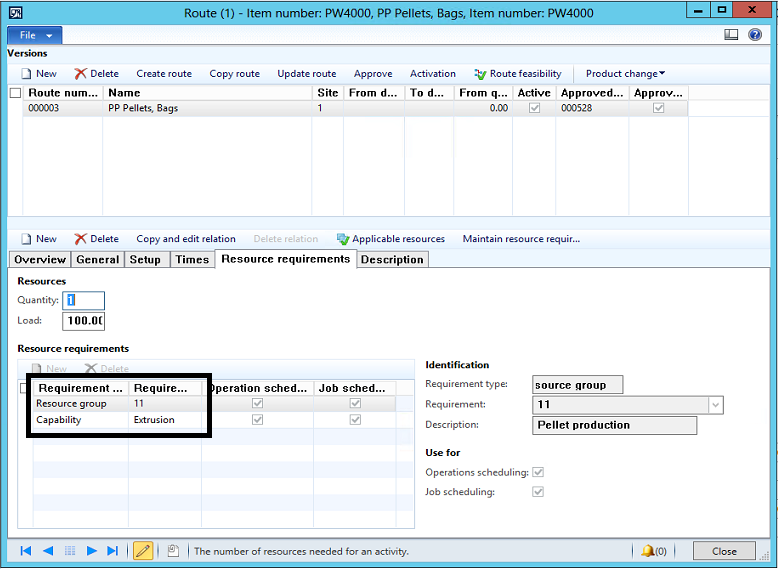

The first operation PPExtCut is consuming MW4004 - Polypropylene and MW4005 - Rubber. An applicable production input location for this operation is found through the Resource requirements for the operation. In the Resource requirements, criteria for finding an applicable resource or resource group during scheduling, is set up

The input location can be specified at the resource group but also on the relation between the resource group and the resource, as it can be seen in below illustration

In case no input locations can be found from the resource groups or resource group relations, then a default production input location is used as a fallback location. This default input location is setup on the warehouse

After setting up the input locations we need to specify which operations that are consuming which materials. This mapping is set up on the material lines using the field Oper. No. This is shown in the below illustration

If no operation is specified on the material line, then the production input location will be found from the resource group or resource group relation, applicable for the first operation in the production route. If no applicable input locations can be found, then the default output location for the warehouse is used. In the diagrams below the defaulting hierarchy is shown. The first diagram shows the rules that applies for finding the production input location for a material line that is mapped to the first route operation or does not have a location defined:

The second diagram shows the rules that applies for finding the production input location for a material line that is not mapped to the first operation but to one of the following operations in the production route:

In order to enable the split of warehouse work a minor change has been introduced to the work template for raw material picking. When a new template is created a Work break is automatically inserted. This work break is configured by the system to group work per route operation. It is possible to remove the work break, and in that case only one work will be generated when releasing to the warehouse from production. In that case the input location found from the first operation in the route will be used as production input location, and if none found on the route the default output location set up for the warehouse

If the hotfix is deployed to an existing installation, then the work template for raw material picking needs to be recreated in order to establish the work break. An alternative is to insert the work break manually in the existing work template.

Again looking at the work details for the released batch order for pellets, we should now understand how the input locations for the two sets of work are found

Summary

In CU8 work for raw material picking can now be split per route operation. On the resource groups and the relation between the resource group and the resource it is possible to setup a production input location to be used in warehouse work. Installing this hotfix on an existing installation will require you to recreate or update the work template for raw material picking. This new capability secures a more efficient picking process for production and batch orders, as the warehouse work will now direct the warehouse worker to the exact locations where the material is consumed.

Comments

- Anonymous

May 21, 2015

Hi Johan, I'm in the need of using formula material consumption in relation with the operation the activity is being performed. As you say in your comments "...After setting up the input locations we need to specify which operations that are consuming which materials. This mapping is set up on the material lines using the field Oper. No. This is shown in the below illustration..."But when I'm trying to achieve so, the 'Oper. No.' field doesn't show any operations.I have already setted up the Route/Operations for the BOMVersion item, which is my manufactured item, the route and route version has been approved and activated.Is there anything I can be missing? - Anonymous

April 01, 2017

I like how it creates work for raw material picking by operation. Is there a way to delay having the raw material picking work show up on the mobile device until it is needed? The scenario is when there are multiple operations and each operation will be performed with days between each operation so the subsequent operations will not need their material until 6 or 7 days after the first operation needs it's raw material. So we want the warehouse worker to pick RM for operation 10 but not for operation 20, 30 or 40 until it gets closer to these operations running in manufacturing? Thanks, John- Anonymous

October 26, 2017

Hi John,For Dynamics 365 for operations (Fall 2017 release) there will be options to release per operation, both as a manual release and with the use of a batch job.Best regards,Johan Hoffmann

- Anonymous