Load demand replenishment - How and thoughts

The last replenishment type is the load demand type.

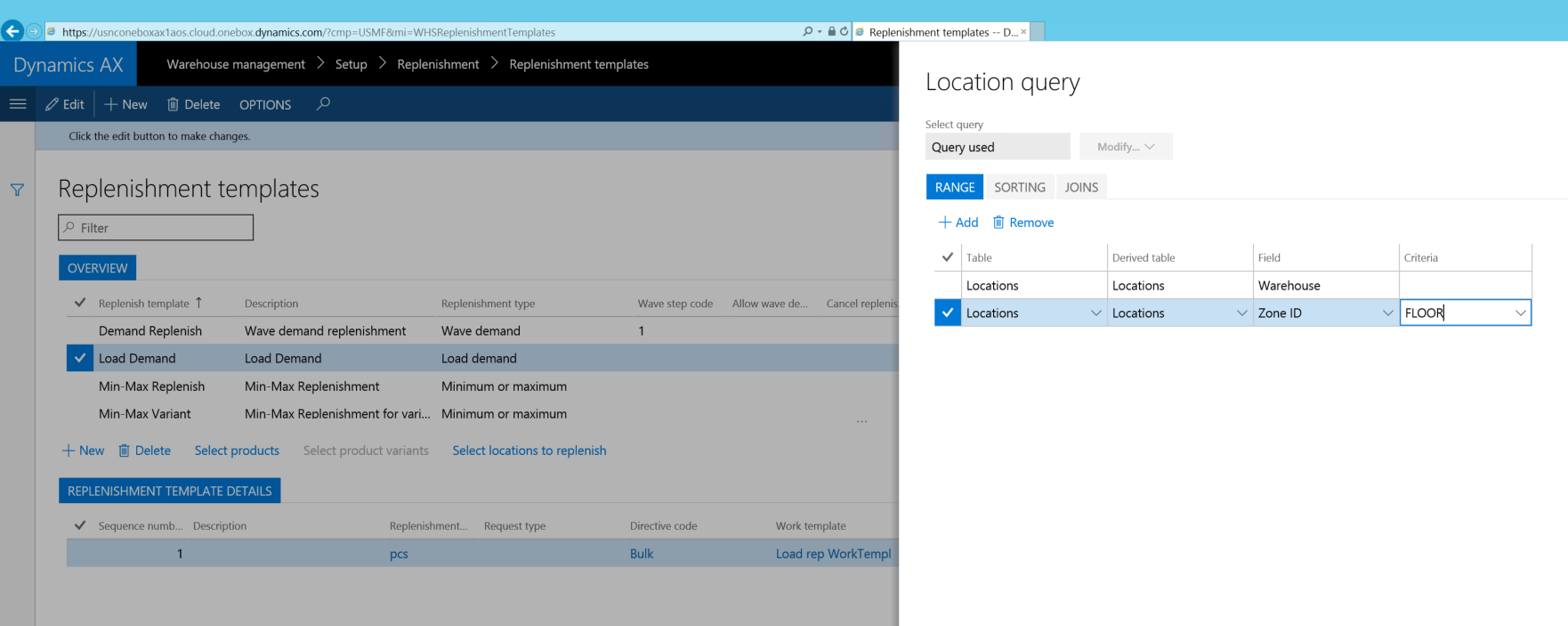

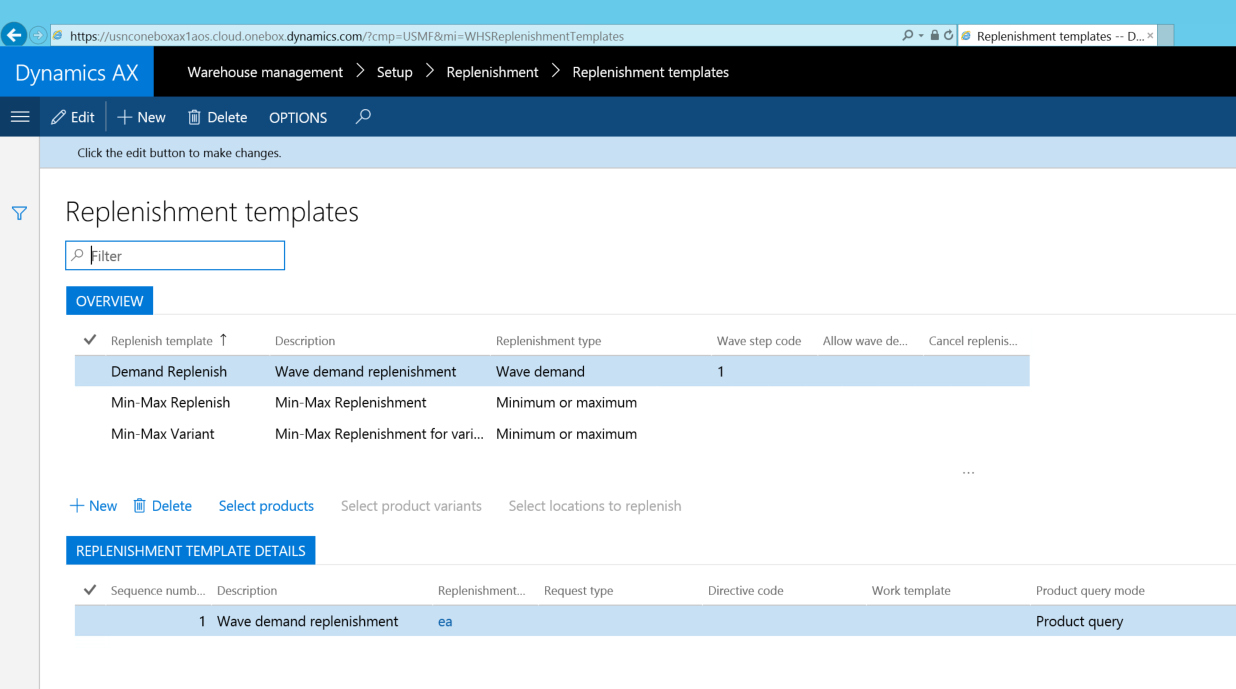

Like the other two types this is setup under WHS>Setup>Replenishment>Replenishment template:

Contoso doesn't have a load replenishment template, so go ahead and create one. Notice that Min and max is gone, the load demand is very simple in terms of setup. Contoso only have one Replenishment work template which is tied to warehouse 61, so here I have created a new replenishment work template. Be careful with directive code, for me it did not work. Under select products I haven't entered anything (all products are fine) and under "Select locations to replenish" I have defined zone = "Floor".

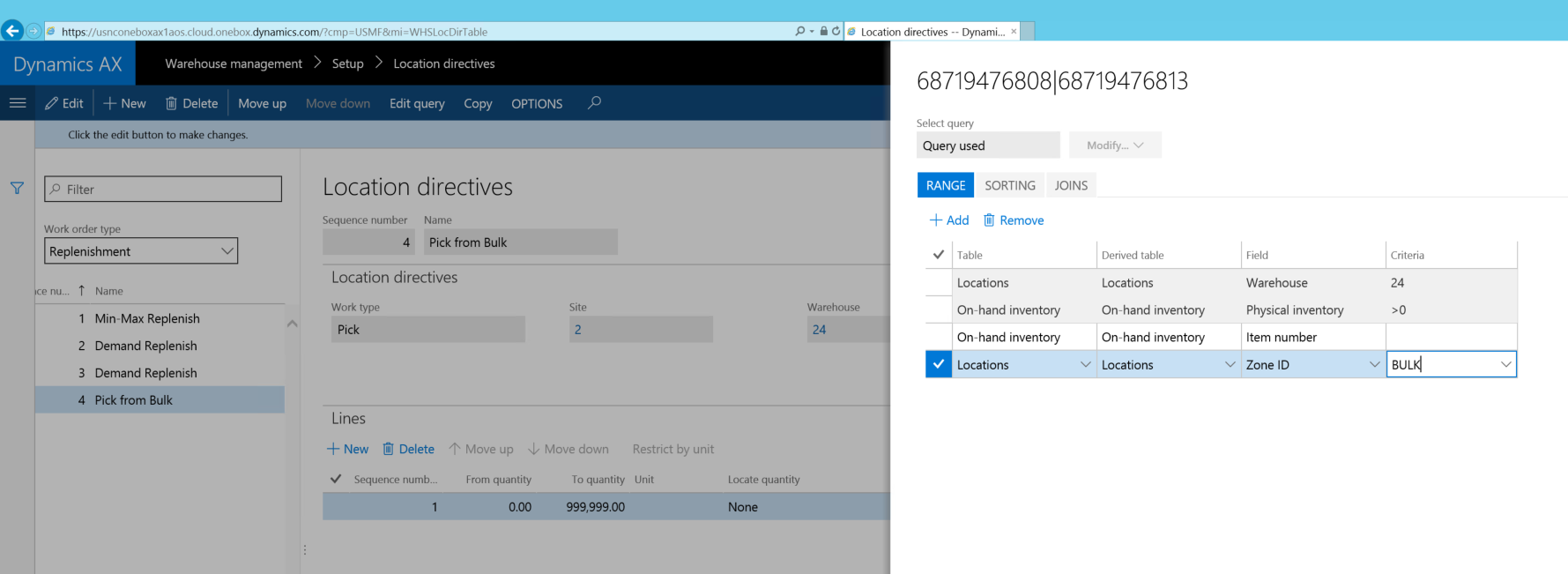

Replenishment location directive have to be setup to do replenishment in Warehouse 24. I choose to pick from zone "Bulk". In my mind it does not make sense to have a put location directive, since that should be defined on the replenishment template however I could not get it to work so please go ahead and create a put location directive. Note that it is not possible to have a put strategy.

At this point we are ready to process the Load demand replenishment template. However we need some data to execute the load demand replenishment template.

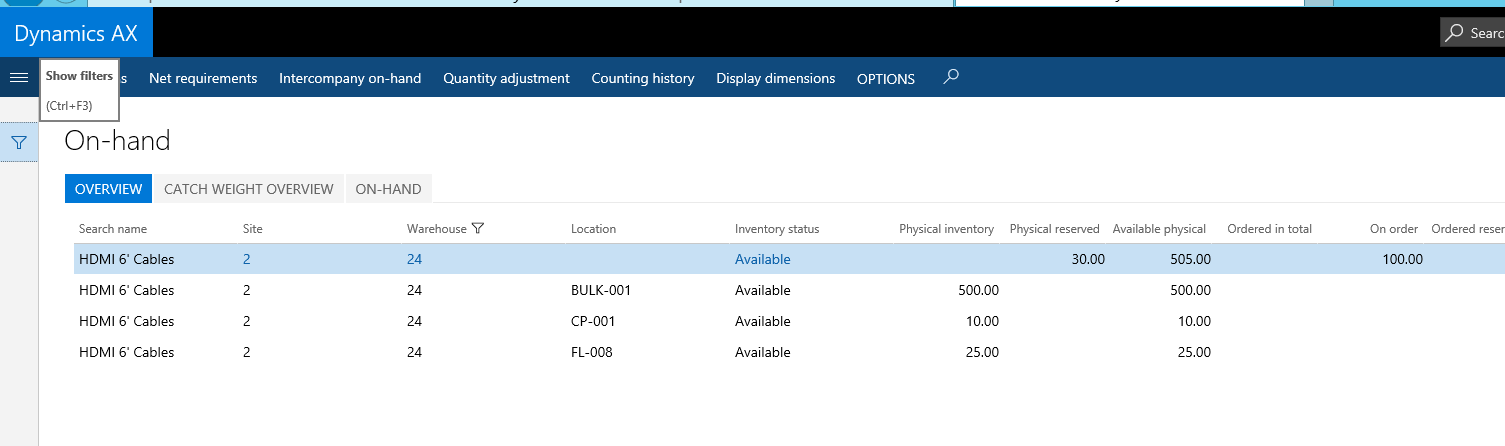

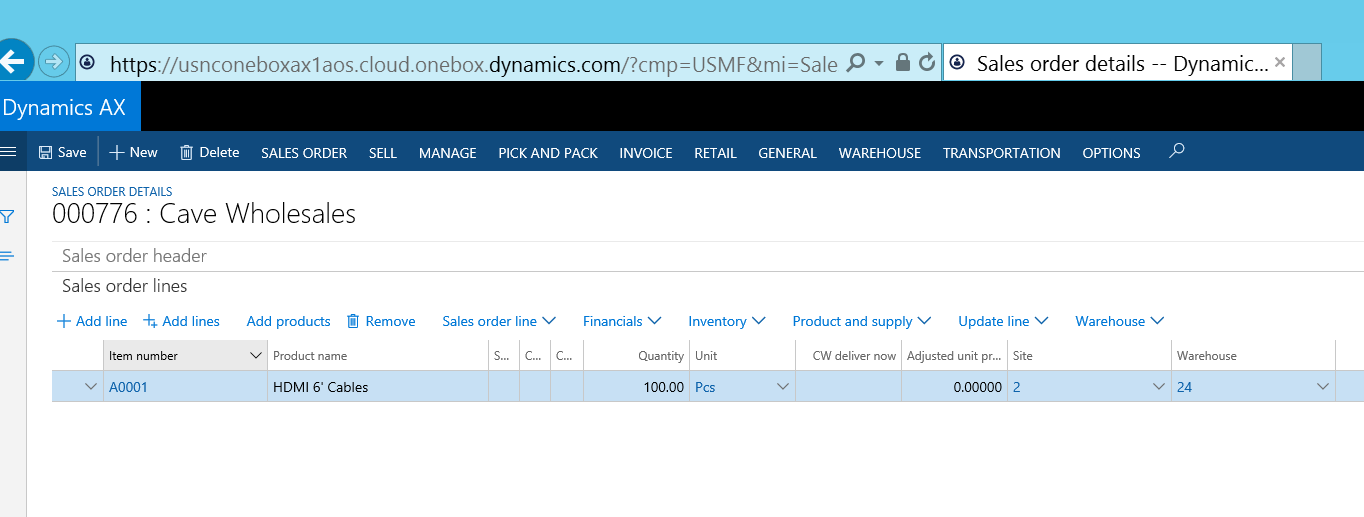

I have created a sales order of 100 A0001

And I have modified the quantities available and where those quantities are available, respectively 25 on a floor location (Pick zone) and 500 on a bulk location. Note that I have not used the first floor location (FL-001).

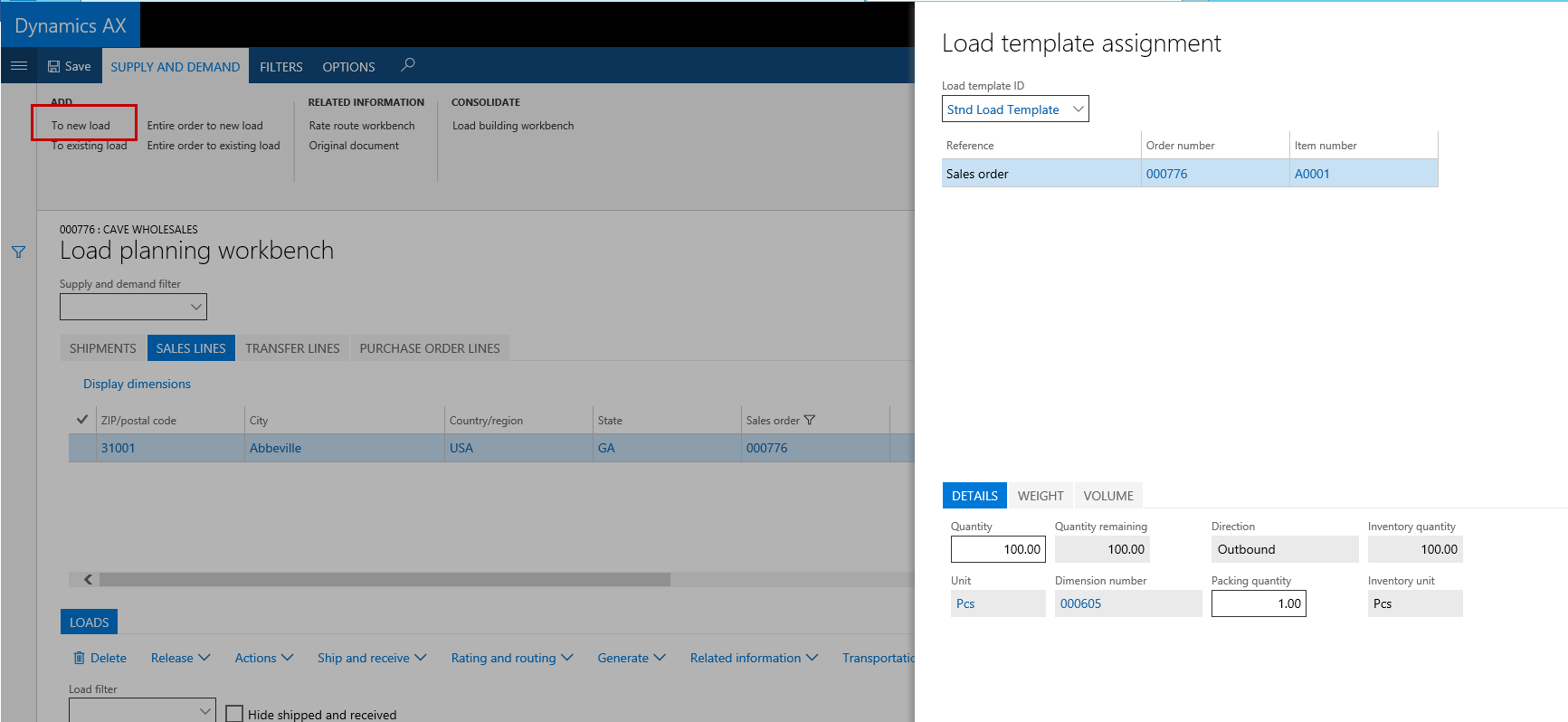

On the sales order I go to the Load planning workbench and release the entire sales order to a new load. I could have done this in a few different ways, for example automatically on sales order creation.

So now I have an open Load of 100 A0001.

I run the "Load Demand replenishment" job under Replenishment with a filter on Open in the Load status

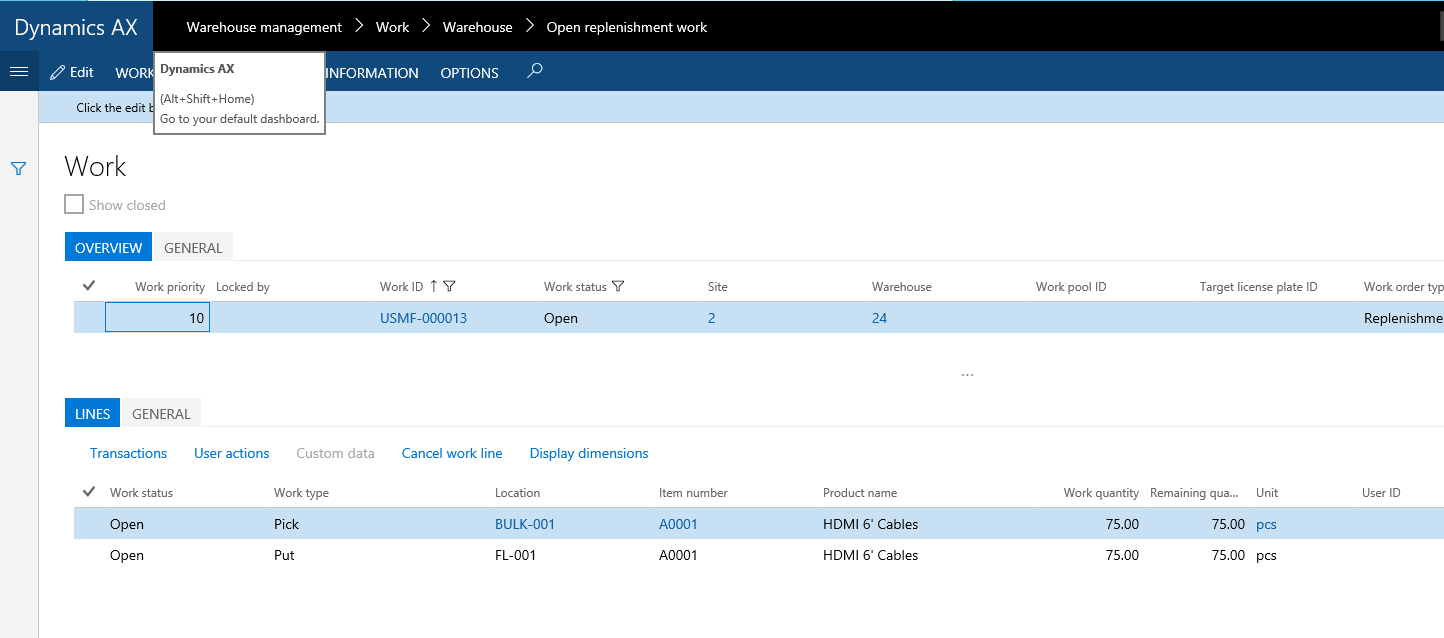

One work header is created:

And now a replenishment job is created to move a quantity of 75 from Bulk to Pick:

Note that the system suggests to put the items on location FL-001 which is odd considering that the FL-008 had 25 pcs. I have earlier figured out that if I (code) overruled the Strategy on the put location directive to "Consolidate" the system will place it together with what I already have in my pick area. I have tried to report it as an error to Microsoft but it ended up in the DCR bucket (please go to Connect and vote it up).

Some general thoughts in terms of Load demand. First and foremost, it is very cool to be able to replenish the pick area based on a set of data that are not yet released to the warehouse. In other words, this allows for replenishing the pick area based on a future "demand" from the pick area. However Load demand operates on Loads, which is good and make sense for companies that use Loads and the "Transportation management" element that entails. I have mainly been working with companies that did not have a manual process of individual parcels but required the automation of the "Automatic release of sales orders" and wave processing and not the load planning workbench and manual release of individual loads.