Process customer returns

Customers can return items to a company for various reasons, such as when an item is defective or if an item doesn't fulfill the customer's expectations.

The return process starts with a request from a customer to return an item, and it progresses to creating a return order in Supply Chain Management.

The two types of return order process are:

Physical return - The return order authorizes the physical return of products.

Credit only - The return order authorizes a customer credit but doesn't require that the customer physically return the products.

The following video demonstrates the customer returns process in Supply Chain Management.

Optimize the customer returns process

Using the Warehouse Management mobile app, your warehouse workers can process return items when they arrive at the warehouse right away with RMA numbers. Return labels can be printed automatically or on demand, and they can be printed as apart of the packing process.

Physical return order process

The tasks that are involved in the physical return order process include:

Create a return order - Formally document the authorization for the customer to return defective or unwanted products. The return order doesn't require that the company accept the returned products or provide a credit for the customer. If the return is accepted, you can authorize a replacement item to be sent before the defective item has been returned.

Inspect items that arrive at the warehouse - Complete an initial inspection and validation against the return order document. The return order also supports quarantine of the returned items for extra inspection and quality control.

Determine disposition - Finalize the inspection process and decide what to do with the returned products. As part of this step, decide whether you want to credit the customer, reject or accept the product return, or scrap the product. Then, you can send a replacement product to the customer.

Generate a packing slip - Generate a packing slip and commit the disposition decision that you made. Finalize the logistics processes.

Generate an invoice - Close the return order.

Credit only process

The tasks that are involved in the credit-only return order process include:

Create a return order - Formally document the authorization for the customer to receive a credit without returning the defective or unwanted products. The Credit only disposition code authorizes the decision to credit the customer without physical return.

Generate an invoice - Generate the credit note and then close the return order.

Return material authorization

Return Material Authorization (RMA) processing builds on sales order functionality. You register an RMA as a return order, which the system creates as a sales order, and it might have another sales order associated with it, called a replacement order. Both sales orders link to the originating RMA number.

Return order

To register an RMA, you need to create a return order, which is a sales order that has the assigned type of Returned order. The system automatically updates the changes that you make to the RMA information in the sales order. Until the return order has the status of Open, it doesn't appear in the list of sales orders.

You can use RMA to handle the arrival and receipt of the returned items and to authorize a credit only disposition action (refer to the section about Disposition codes and disposition actions). You need to handle all other follow-up processes in the sales order.

Replacement order

When you need to ship a replacement order to the customer, the RMA can include a second associated sales order. You can manually create the replacement order for the RMA to support immediate shipment. Alternatively, you can have the system automatically create the replacement order after the arrival, inspection, and receipt are complete for the RMA line item that has a disposition code indicating replacement.

The replacement order has the same functionality that's associated with a sales order. For example, you can use it to complete the following tasks:

Set up a custom product as the replacement item.

Create a production order to repair a returned item.

Create a direct delivery purchase order to send the replacement from a vendor.

Support other purposes.

Create a return order header

The return order process starts when a customer contacts your organization to return a defective or unwanted product and/or it's to be credited. After your organization accepts the return, you document it by creating a return order. This return order becomes the focal point of the internal processing of the returned product.

When you create a return order, you must include information from the following table.

| Field | Description | Comments |

|---|---|---|

| Customer account | A reference to the Customers table | You must provide an existing customer account. |

| Delivery address | The address that the item is returned to | By default, the system uses the organization’s address. If you select a specific warehouse on the header, the system changes the delivery address to the delivery address of the warehouse. You can change this address on the Return order details page. |

| Site/warehouse | The site or warehouse that receives the returned product | The delivery address for the return order is determined based on the delivery address of the site or warehouse. |

| RMA number | The ID that’s assigned to the return order | The system uses the RMA number as an alternate key throughout the return order process. The RMA number that the system assigns is based on the RMA number sequence that’s set up on the Accounts receivable parameters page. |

| Deadline | The last date that an item can be returned | The system calculates the default value as the current date plus the period of validity. For example, if a return is valid for only 90 days from the date when the return order is created, and the return order was created on May 1, the value in the field is 30-July. You can set the period of validity on the Accounts receivable parameters page. |

| Return reason code | The customer’s reason for returning the product | Select the reason code in the list of user-defined reason codes. You can update this field anytime. |

Create return order lines

After you complete the return order header, you can create return lines by using one of the following methods:

Enter the item details, quantity, and other information for every return line manually.

Create a return line by using the Find sales order function.

We recommend that you use the Find sales order function when you create a return order. The function establishes a reference from the return line to the invoiced sales order line and retrieves line details such as item number, quantity, price, discount, and cost values from the sales line. The reference helps guarantee that, when the product is returned to the company, it's valued at the same unit cost that it was sold at. The reference also validates that return orders aren't created for a quantity that exceeds the quantity that was sold on the invoice.

Charges

You can add fees and charges to the return order through one or more of the following methods:

Add charges manually to the return order header, the return order line, or both.

Have the system automatically add charges to the return order header as a function of the return reason code.

Have the system automatically add charges to the return order line, based on the disposition code of the line.

The system automatically adds charges after you assign a return reason code or disposition code to the line. If you change the reason code later, the system doesn't remove the existing charge entry, but it might add a new charge entry based on the new reason code.

When you add charges to return order lines, charges that the system calculates as a percentage of the line or order value become negative when the line or line order is negative, unless the percentage is also a negative number. A charge that has a negative value represents a credit to the customer.

Return reason codes

By applying reason codes to returns, you can help make return patterns easier to analyze. Reason codes provide information about why a customer wants to return items. Some organizations have many reason codes. These organizations might group the reason codes into reason code groups to gain a better overview and for accumulated reporting.

Disposition codes and disposition actions

An important step in the return order process is the assignment of a disposition code to the return order line as part of arrival registration. The disposition code determines the following information:

Financial implications - Determines whether you should credit the customer for the returned items and if you should add charges to the return order line.

Disposition of the returned item - Determines whether you can add the item back to inventory or not, if you should scrap the item, or if you should return the item to the customer.

Logistics of the returned item - Determines if you should issue a replacement item to the customer.

In addition to determining how the returned goods are disposed of, disposition codes can cause the system to apply charges to the return line. You can also use the codes to group returns for statistical analysis. You would define disposition codes as part of the return order setup.

Each disposition code must reference one of the available disposition actions. The financial and logistic implications of each disposition action are:

Credit only - The customer is credited the sales price minus fees or charges. Loss from scrapping the item is posted to the ledger. The item shouldn't be returned. This disposition action is used when:

Enough trust exists among the parties.

The cost of returning the defective item is prohibitive.

The items can't be allowed back into inventory. Because of other conditions, a physical return isn't required.

Credit - The customer is credited the sales price minus fees or charges. The inventory value is increased by the cost of the returned item. The item is returned and added back into inventory.

Replace and credit - The customer is credited the sales price minus fees or charges. Inventory value is increased by the cost of the returned item. A separate sales order for a replacement is created and handled separately. The item is returned and added back into inventory.

Replace and scrap - The customer is credited the sales price, minus fees or charges. Loss from scrapping the item is posted to the ledger. A separate sales order for a replacement is created and handled separately. The item is returned and scrapped.

Return to customer - No financial implications, except fees or charges. The item is returned but is sent back to the customer after inspection. This disposition action might be used if the item has been deliberately damaged or if the warranty has been voided.

Scrap - The customer is credited the sales price minus fees or charges. Loss from scrapping the item is posted to the ledger. The item is returned or scrapped.

Although, disposition codes can be helpful, they are not required immediately upon receiving a returned item. Your warehouse workers can postpone disposition codes until after they have reviewed and inspected the item. They can create return orders using the Warehouse Management mobile app to gain greater control and flexibility over the return process. Blind receiving and details receiving process can be implemented on the Return item receiving menu item. You can enable these features by navigating to Warehouse management > Setup > Warehouse management parameters.

Arrival at the warehouse for inspection

Before you can physically receive returned items into inventory by posting a packing slip, the items must go through arrival registration and an optional inspection. The following sections describe each step.

The process has several other variations that aren't covered in this unit:

Don't use the Arrival overview list to create an Arrival journal. Instead, manually create the Arrival journal. Return orders have Sales order as the reference.

Generate pallet transports if you're using Warehouse management. The return line has a status of Arrived during pallet transport.

Register the arrival of the returned item directly from the return order line by using the Registration function.

During the arrival process, the system integrates returns with the general process for warehouse arrivals. The arrival process also supports the creation of quarantine orders for returned items that must undergo a separate inspection.

Identify products in the Arrival overview list

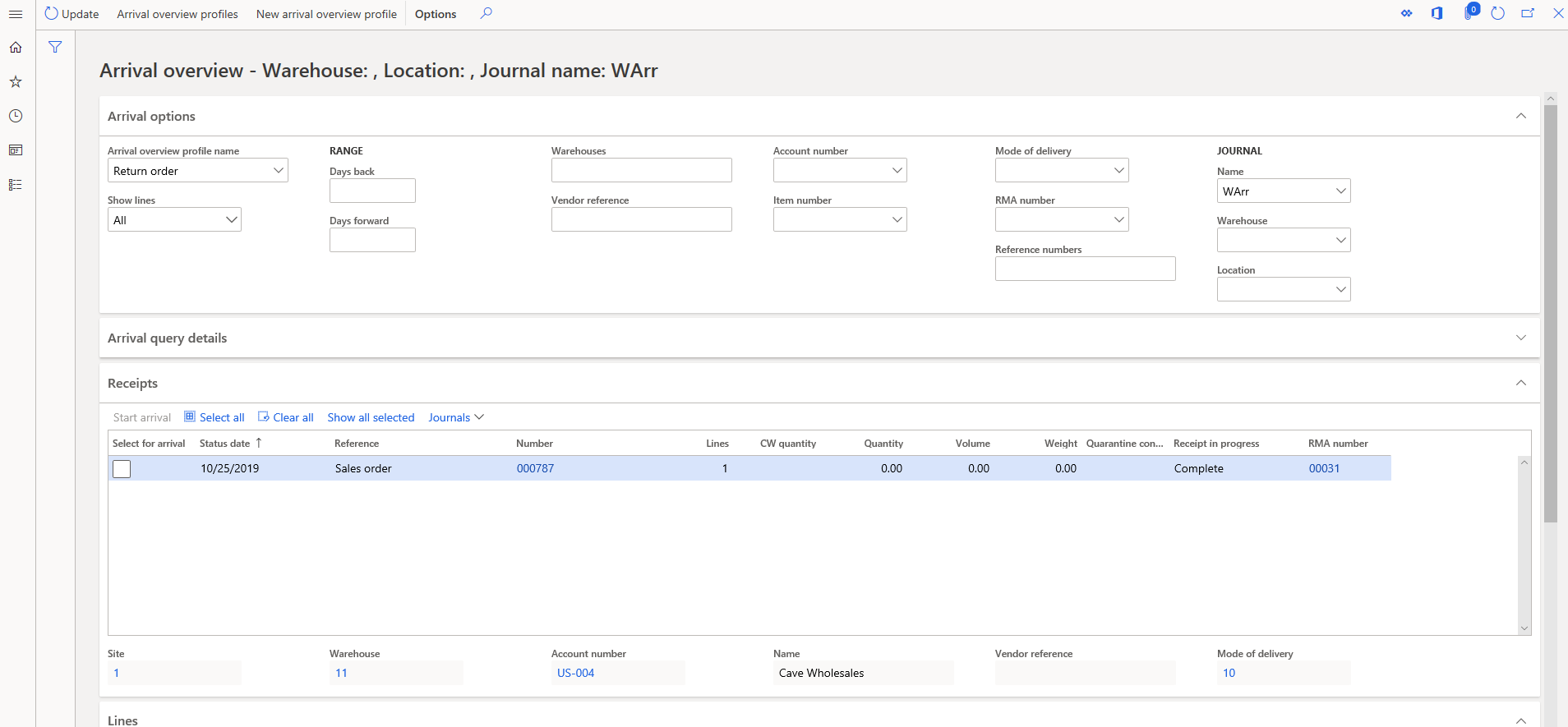

The Arrival overview page lists all planned incoming arrivals.

You must process arrivals from return orders separately from other types of arrival transactions. After you identify an incoming package on the Arrival overview page (for example, by using the accompanying RMA document), on the Action Pane, select Start arrival to create and initialize an Arrival journal that matches the arrival.

You can view arrivals on the Arrival overview page by going to Inventory management > Inbound orders > Arrival overview.

Edit the Arrival journal

By setting the Quarantine management option to Yes, you can create a quarantine order for the return line. If a line is sent to quarantine for inspection, you can't specify a disposition code.

If you set the Quarantine management option to Yes in the item's inventory model group, the Quarantine management option on the Journal lines page is marked for the Arrival journal line, and you can't change it. If the line is sent to quarantine, you must specify the appropriate quarantine warehouse.

If the arrival line isn't sent for inspection, the warehouse arrival clerk must specify the disposition code directly on the Arrival journal line, and then post the Arrival journal. If you shouldn't assign the same disposition code to the whole quantity of the return line, or if the full quantity of the line hasn't been received, you must split the line.

When you split an Arrival journal line, you must also split the return line (SalesLine) and create a new lot ID. You can split the line by reducing the quantity of the Arrival journal line. When you post the journal, the system creates a new return line that has a status of Expected for the remaining quantity. You can also split the line by selecting Functions > Split.

Process the quarantine order

If the returned products are sent for inspection at the quarantine warehouse, you would complete extra processing in a quarantine order. You should create one quarantine order for each arrival line that's sent to quarantine. The disposition code indicates the result of the inspection process.

You can split a quarantine order as you would split the Arrival journal. If you split the quarantine order, you cause a corresponding split of the return line. After you enter the disposition, complete the quarantine order by using the End function or the Report as finished function. If you select Report as finished, the system creates a new arrival in the designated warehouse. Then, you can process this arrival by using the Arrival overview page.

If the arrival originates from a quarantine order, you can't change the disposition code that is assigned during inspection. If you complete the quarantine order by using the End function, the system automatically registers the lot. Sometimes, an item might be sent back from quarantine to the Shipping and receiving department. For example, the quarantine inspector might not know where to store the item in inventory. In this case, you must update the corresponding packing slip to correctly register and act on the disposition code that's specified because of the quarantine.

You can send acknowledgment of receipt to the customer when the return line is registered. The Return acknowledgment report resembles the return order document. You don't journalize or otherwise register the Return acknowledgment report in the system, and it isn't a required step in the return order process.

Replace a product

The two methods for managing product replacement are:

Up-front replacement - Replace a product before you receive the returned product from the customer.

Replacement by disposition code - Automatically create a new replacement order line.

Up-front replacement

In up-front replacement, you can deliver the replacement item to the customer before the item is returned. For example, this method is useful if the item is a machine part that can't be removed unless a spare part is available to take its place, or if you want your customer to have the replacement product immediately.

The up-front replacement order is an independent sales order. The header information is initialized from the customer, and the line information is initialized from the return order. You can edit, process, and delete the replacement order independently of the return order. When you delete a replacement order, you receive a message that the order was created as a replacement order.

The return order includes a reference to the replacement order. If you create an up-front replacement order for a return order before the defective item is returned, you can't select disposition codes for replacement after the defective item has been returned.

Inspect and process returned items more efficiently

Warehouse operators have enhanced control and flexibility over the customer return process, allowing them to inspect returned goods before selecting a disposition code. This feature streamlines the management of returned items by enabling operators to postpone the disposition decision until after inspection. Additionally, warehouse workers can create return orders using the Warehouse Management mobile app, implementing blind receiving and return details processes. The return label process has also been improved, allowing labels to be printed during manual packing and introducing a new batch job for cleaning up return data and expiration dates after the validity period. These enhancements boost productivity and improve the user experience for businesses managing customer returns in the warehouse.

Replacement by disposition code

In the replacement by disposition code method, you deliver the replacement item by using an independent sales order: the replacement sales order. The system creates this sales order when you generate the packing slip for the return order.

The order header uses information from the customer that's referenced on the return order header. The system collects the line information from the information on the Replacement item page. Make sure that you fill in the Replacement item page for lines that have disposition actions that start with the word "replace".

However, neither the quantity nor the identity of the replacement item is validated or limited. This behavior allows for cases where the customer wants the same item but in a different configuration or size, and cases where the customer wants a different item. By default, the system enters an identical item on the Replacement item page. However, you can select a different item, if the function is set up. You can edit and delete the replacement sales order after it's created.

Generate a packing slip

Before you can receive returned items into inventory, you must update the packing slip for the order that the items belong to. Similar to how the invoice update process is the update of the financial transaction, the packing slip update process is the physical update of the inventory record. In other words, this process commits the changes to inventory. In the case of returns, you would implement the steps that are assigned to the disposition action during the packing slip update. When you generate the packing slip, the following events occur:

In the warehouse, personnel use the standard process to perform a physical receipt. They generate ledger postings if the inventory model group (Post physical inventory) and the Accounts receivable parameters (Post packing slip in ledger) are set appropriately.

Warehouse personnel scrap items that are marked with a disposition action and that contain the word "scrap". Then they post the inventory loss to the ledger.

Warehouse workers receive and deliver items that are marked with the Return to customer disposition action. These items have no net effect on inventory.

A sales manager creates a replacement sales order. This sales order is based on information on the Replacement item page.

You can generate the packing slip only for lines that have a return status of Registered, and only for the full quantity on the return line. If several lines on the return order have the Registered status, you can generate the packing slip for a subset of the lines by deleting the other lines from the Post packing slip page.

Partial returns are defined in terms of return order lines, not in terms of return order shipments. Therefore, if you receive the full quantity that's indicated on one return order line, but you receive nothing from the other lines on the return order, the delivery isn't a partial delivery.

However, if a return order line requires that 10 units of an item be returned, but you receive only four units, the delivery is a partial delivery. If not all expected return items arrive, you can set the shipment aside, and then wait for the rest of the returned quantity to arrive. Alternatively, you can register and post the partial quantity.

As part of the process for posting packing slips, you can associate the packing slip reference number from the customer's shipping documents with the order lines. This association is optional and is for reference only. It doesn't create transactional updates.

In general, you can skip the packing slip process and go directly to invoicing. In this case, you complete the steps that you would perform during packing slip generation during invoicing instead.

Generate an invoice

Though the Return order page contains the information and actions that are required for handling the special logistical aspects of the return order, you must use the Sales order page to complete the invoicing process. Then, your organization can invoice return orders and sales orders at the same time, and the same person can complete the invoicing process as required.

To view the return order from the Sales order page, select the link for the sales order number to open the associated sales order. You can also find the return order on the All Sales orders page. Return orders are sales orders that have an order type of Returned order.

Credit correction

As part of the invoicing process, verify that miscellaneous charges are correct. To cause the ledger postings to become corrections (Storno), consider using the Credit correction option on the Other tab of the Posting invoice page when you post the invoice/credit note.

Post to the ledger

The ledger postings that the system generates when you invoice the return order are influenced by a few important settings and parameters:

Return cost price - For inventory models other than Standard cost, the Return cost price parameter determines the cost of the item when it's accepted back into inventory or scrapped. To calculate a correct valuation of inventory, it's important that you set the Return cost price parameter correctly. If you use the Find sales order function to create a return order line that has a reference to a customer invoice, the Return cost price value is equal to the cost price of the item that's sold. Otherwise, the cost price value comes from the item setup or you can enter it manually.

Credit correction/Storno - The Credit correction parameter on the Posting invoice page determines whether the system should record postings as positive (DR/CR) entries or as correcting, negative entries.