Overview of the procure-to-purchase process

The procurement cycle begins with products and vendors. You can use the Product information management module to define and create products and product variants that you purchase from your vendors. When products have been defined and created, you can authorize the products for use by releasing the products to legal entities.

For more information about how to create products, see Create products and product masters in Dynamics 365 Supply Chain Management.

Procurement and sourcing workspace

Procurement and sourcing covers all the steps from identifying a need for product and services through procuring the product, receipt, invoicing, and processing of payment with vendors. Procurement processes can be configured toward specific business needs by defining purchasing policies and workflows.

Identifying a need for product and services

The need for products or services may arise from requisitions, for example, when an employee requires a product. Product catalogs can be set up to guide the selection of available products to select from, or requests can be made for products that are not yet made available in a catalog, allowing the purchasing department to consider how the product can be supplied.

Spending limits can be used to constrain requisition spending, and the purchasing workflow adds the option of requiring approval before ordering happen. It's also possible to specify budget fund allocation, if required.

The procurement department identifies suppliers for required products and services, and this can involve a request for quotation being sent out to multiple potential suppliers. It's possible to share the specifications of the product that's being requested and potential vendors can view these to see if they can deliver a product that conforms with them. Vendors return their bids which are then reviewed by the procurement department before they select the supplier that they want to procure from.

Purchase orders include an option to send out a purchase inquiry to the vendor as an alternative to a more comprehensive request for quotation process. The purchase inquiry can be used to help establish terms like prices, discounts, and delivery date for the order. If vendors are set up to use the Vendor portal, purchase inquiry functionality is disabled. Instead the order is shared on the Vendor portal, and when a confirmation request is sent the vendor can directly confirm the order.

Vendor catalogs can be used to collect information on the product assortment that vendors can supply. Vendors can publish their own catalog, so it's easier to keep the catalog up to date. It's possible to attach an approved vendor list to a product, and this can help guide vendor selection when new purchase orders are opened, and prevent the use of unintended vendors.

Procurement

Purchase orders can be created in several ways including:

- As an outcome of master planning which has identified a demand that requires a purchase. This process generates planned purchase orders, and when these are released, purchase orders are generated.

- Through the processing of purchase requisitions that result in procurement.

- Through the processing of purchase agreements, where purchase orders are created as released orders from the agreements. This is commonly used when purchase agreements are used to represent blanket orders.

- Manually, when the purchase order that's created is not based on another document.

Purchase orders that are configured with purchase approval workflows require approval before they are recorded as approved, and this is required before the order can be processed further.

Purchase orders are confirmed to represent that an agreement has been established with the vendor. The purchase order will then gradually progress through different states until ultimately being invoiced or canceled.

When you create a purchase order, many of the fields are pre-populated with values that default from the information stored about the vendor in the Vendors page. This means that there are a limited number of fields that you need to fill in on the purchase order, although you can choose to override the default values.

Prices and discounts

Prices and discounts include information about the prices, discounts, and rebate terms that they offer. Prices and discounts can be represented as trade agreements. Trade agreements represent vendor price lists with prices or discounts, and have a specific set of dates for which the agreement is valid. Prices and discounts can be negotiated and represented through purchase agreements with conditions like commitments to buy certain volumes or monetary amounts as a precondition for the negotiated terms. Rebate agreements can be created with vendors where the procurement of specific products or groups of products may trigger a rebate from the vendor depending on the purchase amount or volume.

Delivery options

There are different options for the delivery process associated with a purchase order. Ordered products can be split into delivery schedules, where parts of the ordered quantity can be planned for delivery on different dates. Delivery can also include direct delivery initiated from a sales order, which automates the generation of the packing slip on the sales order at the same time as the product receipt is recorded on the purchase order. Purchase orders can also be part an intercompany order chain, also referred to as intercompany purchase orders, where products are ordered from a matching intercompany sales order. In this situation, some steps are automated across the two related intercompany orders.

Supplementary items

Products can be set up to include supplementary items. This is to propose products that are related to the product that's being ordered. The additional products may be required, or may be optional. In some cases, supplementary items may be added as free products that accompany the purchase of other products.

Purchase order charges

Charges can be assigned to the purchase order. This can happen automatically through setup of automatic charges or by adding the charges manually. Charges can be assigned to the order at the header level, or at the order line level. Accounting of charges can be set up in different ways. For example, you can set up a charge to be accounted as a product cost. If you do this, the charges must be assigned at the order line level before the order can be confirmed. There is an option that can help allocate charges from the order header to the lines.

Product receipt and invoicing

Purchase orders that include physical products commonly require arrival registration to happen within a warehouse, and after this a product receipt is registered for the order. Purchase orders with products that fulfill requisitions may be configured so that the employee who has requested the products also needs to provide a confirmation of receipt.

Some purchase orders include products that are services or other non-physical products where receipt in a warehouse is not needed. Products can be created as services or procurement categories can be used directly on the purchase order for such orders. With these orders, accounting of product receipt is sometimes skipped and the order is invoiced directly, or alternatively product receipt registration is done on the purchase order without any prior arrival registration.

Receipt of products may result in automatic consumption for a specific purpose. This includes implied consumption with direct delivery, consumption towards a project, or accounting the product as a fixed asset.

When vendor invoices arrive from the vendor they may first be recorded in the invoice register independent of the purchase order, and then later approved as a record against the purchase order. Recording the vendor invoice with the purchase order includes matching of the product receipt toward the invoice.

Accounting distributions can be specified on the purchase order to describe how accounting should be done within the ledger, and can also define how budget fund allocation is obtained when this is included in your configuration. Invoiced purchase orders will record the liability into the vendor account within accounts payable, from where the vendor payment can be processed.

Vendor performance

Performance and review of purchasing is supported through procurement and account payable reports, which include spend analysis and vendor performance analysis.

Confirmed purchase orders with changes workspace

Your organization can leverage the Confirmed purchase orders with changes workspace to access the confirmed purchase orders that have been changed since confirmation. Procurement professionals can review any changes made to purchase orders that have been previously confirmed and alleviate the downstream impacts. This workspace is enabled in Dynamics 365 Finance and Operations by default, but your organization can enable AI-powered and Copilot functionality to generate summary of impact and proposed communication content. For more information on how to enable this feature, go to Enable Copilot support for managing changes to confirmed purchase orders.

At the top of the workspace, three tiles summarize groups of changes to confirmed purchase orders and the related impact on downstream demand:

Low impact changes: This tile highlights changes to purchase orders that have no known impact on downstream demand. No known impact is assumed if changes to the quantity or delivery dates don't affect those requirements from demand. Examples of these changes include an increased quantity or an earlier date. A summary of changes is generated to help you review and validate the purchase orders.

High impact changes: This tile highlights purchase orders that have known downstream impacts on demand. These changes are summarized together with the detected demand impacts, thereby helping you to investigate further and decide what action to take.

Impacted downstream orders: This tile summarizes impacts on different kinds of downstream demand orders by total, per type of order. This information helps you review potential impacts on demand and identify each originating change.

Each tile provides a Show link. When you select this link, the view beneath shows the changes to supplying purchase orders and the affected demand according to the tiles's classification and filter.

Procurement workflow

Some organizations require that purchase requisitions and purchase orders are approved by a user other than the person who entered the transaction. To set up an approval process, you can create a workflow.

A workflow represents a business process. It defines how a document flows through the system and indicates who must complete a task or approve a document. There are several benefits of using the workflow system in your organization:

- Consistent processes — You can define the approval process for specific documents, such as purchase requisitions and expense reports. Using the workflow system helps to ensure that documents are processed and approved in a consistent and efficient manner.

- Process visibility — You can track the status, history, and performance metrics of a specific workflow instance. This helps you determine whether changes should be made to the workflow to improve efficiency.

- Centralized work list — Users can view a centralized work list to view the workflow tasks and approvals assigned to them across all workflows they participate in. This is available in the Work items page.

The following workflow types are available for Procurement and sourcing.

| Type | Use this type to |

|---|---|

| Purchase requisition review | Create review and approval workflows for purchase requisitions. |

| Purchase requisition line review | Create review and approval workflows for purchase requisition lines. |

| Purchase order workflow | Create review and approval workflows for purchase orders. |

| Purchase order line workflow | Create review and approve workflows for purchase order lines. |

| Vendors add application workflow | Create review and approval workflows for adding new vendors via vendor requests. |

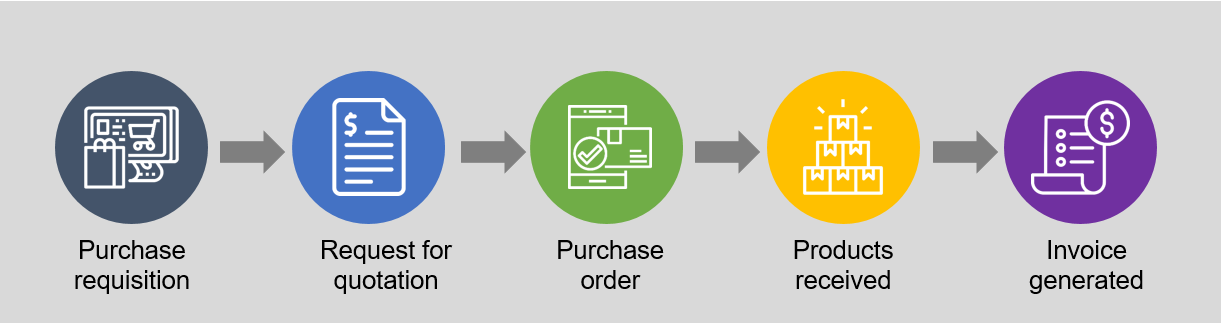

Purchasing process

The need for products or services might arise from requisitions, like when an employee requires a specific product to perform their job. This might be a laptop or office supplies for example. The high-level process for purchasing is as follows.

- Purchase requisition creation from the requester.

- Request for quotation (RFQ) to the vendor or vendors.

- Once the vendor is selected, the RFQ is converted to a purchase order or a purchase order is created.

- The products are received into inventory.

- The invoice is generated.

Product catalogs can be set up to guide the selection of available products to select from, or requests can be made for products that are not yet made available in a catalog, allowing the purchasing department to consider how the product can be supplied.

Spending limits can be used to constrain requisition spending, and the purchasing workflow adds the option of requiring approval before ordering happens. It's also possible to specify budget fund allocation, if necessary.

The procurement department identifies suppliers for required products and services, and this can involve a request for quotation being sent out to multiple potential suppliers. It's possible to share the specifications of the product that's being requested, and potential vendors can view these to see if they can deliver a product that conforms with them. Vendors return their bids, and then the procurement department will review the bids prior to selecting the supplier that they want to procure from.

Purchase orders include an option to send out a purchase inquiry to the vendor as an alternative to a more comprehensive request for quotation process. The purchase inquiry can be used to help establish terms like prices, discounts, and delivery date for the order. If vendors are set up to use Vendor collaboration, purchase inquiry functionality is disabled. Instead, the order is shared on the Vendor collaboration interface, and when a purchase order is sent, the vendor can directly confirm the order.

Work with purchase requisitions

Depending on the setup of your organization, you can create purchase requisitions for products that your organization uses.

In the purchasing policies, you define the default behavior of the purchase requisition and decide if the user can select what type of purchase requisition they can create.

The replenishment requisition can only have lines with items because it is preparing lines for master planning to pick up as a Demand for specific site or warehouse. Master planning generates the planned purchase or transfer orders depending on the item coverage policies.

Therefore, when the replenishment requisition is approved, items are ready to be picked up by master planning. Alternatively, a purchase requisition for consumption is used for generating purchase orders directly.

If your organization requires indirect products (products that are not required by master planning), you can submit purchase requisitions for those products. A purchase requisition is an internal document that authorizes the Purchasing department to buy items or services. The Purchasing department can use purchase requisitions to generate the actual purchase orders for the items.

Purchase requisitions are internal documents, whereas purchase orders are the equivalent of external documents that the Purchasing department submits to vendors.

You can use a purchase requisition to submit a request for items or services that you require to perform your job function. By using purchase requisitions, you can:

- Order items and services from a hosted procurement catalog or from a vendor catalog that is hosted on an approved vendor's website.

- Submit a requisition for a non-catalog item if this action is supported by your purchasing policies.

- Create a requisition on behalf of someone else if you have been granted the proper permissions for your user role.

Purchase requisitions require that you define a purchase requisition workflow. This workflow controls the approval process of the purchase requisition from when it is submitted to the workflow until it is approved, after which purchase orders are created and submitted to vendors.

Requisitions that have a purpose of consumption

A requisition that has a purpose of consumption represents demand for items or services that will be used internally by your organization. The demand that is created by this kind of requisition is always fulfilled by a purchase order. If Supply Chain Management is set up to automatically generate purchase orders, purchase orders are created after the purchase requisition is approved.

Requisitions that have a purpose of replenishment

A requisition that has a purpose of replenishment represents demand to replenish inventory.

For example, you create a requisition to replenish items so that they can be sold at a specific retail location at a specific time. The demand that is created by this kind of requisition can be fulfilled by a purchase order, transfer order, production order, or kanban.

When the requisition purpose is replenishment, demand is expressed as a quantity instead of a monetary amount. Therefore, encumbrance accounting, budgetary control, business rules for fixed asset determination (BRAD), project accounting, and any related rules don't apply. Only products that are stocked and released to the specified legal entity can fulfill replenishment requisition demand. To define the products that are available when the requisition purpose is replenishment, use the Replenishment category access policy rule page.

To use purchase requisitions that have a purpose of replenishment, you must set up master scheduling to include requisition demand. The fulfillment method for the demand that is created by this kind of requisition is then determined automatically, based on the supply policies that have been set up for the items in your organization and planned by using master scheduling.

Create and send a request for quotation

You can send a request for quotation (RFQ) to vendors to request information about prices and delivery times for products. Organizations issue an RFQ when they want to buy items or services and want to receive competitive offers from several vendors.

In an RFQ, you ask vendors to provide the prices and delivery times for the quantities of products that you specify. You can also ask vendors to specify if there are any incidental charges, such as shipping costs. You might ask if the vendor offers discounts for large orders or early payment of the vendor invoice.

The RFQ process covers:

- Creating and sending an RFQ to one or more vendors.

- Receiving and registering RFQ replies.

- Transferring accepted RFQ replies to a purchase order, purchase agreement, or purchase requisitions depending on the type of RFQ.

- Transferring the reply from a vendor to a trade agreement journal.

Create and manage purchase orders

A purchase order is a document that is generated by a buyer that authorizes the purchase of products. When the document is accepted by the vendor (or seller or products), it becomes a contract binding on both parties.

A purchase order defines the descriptions, quantities, prices, discounts, payment terms, date of performance or shipment, and other associated terms and conditions, in addition to identifying a specific seller.

Many different roles and users can use purchase orders to update and keep track of the status of the orders. For example, the purchasing agent uses purchase orders to create a list of products that are to be purchased from a specific vendor.

Information such as price, delivery information, and items are recorded into the purchase order. Additionally, the purchasing agent will generate a purchase order confirmation document that is the external document sent to the vendor to notify them of the purchase. When the items are received, they need to be received into inventory, then an invoice can be generated.

Work with purchase agreements

A purchase agreement is a contract that commits an organization to buy a product in a certain quantity or amount over a period in exchange for special prices and discounts. The prices and discounts of the purchase agreement overrule any prices and discounts stated in any trade agreements that exist.

A purchase agreement has a validity period that is defined by the person who creates it. The delivery date of a purchase should be within the validity period. Additionally, a purchase agreement is on hold by default. You can order from a purchase agreement only when it is set to Effective.

Purchase agreements are an optional feature that can be added into the procurement process. Purchase agreements can set default prices and discounts and can be linked to a purchase requisition. You can also create a purchase agreement from a reply of requests for quotes. When a purchase agreement is linked to a document, the link will be copied to other transactions and documents that are created from the document.

For example, if an agreement is linked to a purchase requisition, when the purchase requisition is approved and the purchase order is created, the purchase order will automatically have a link to the purchase agreement.

Approve POs and requisitions from mobile device

To streamline purchase approvals, Dynamics 365 Supply Chain Management offers a mobile approval experience, enhancing flexibility and responsiveness. This allows users to manage approval tasks for purchase requisitions and orders directly from their mobile devices, improving efficiency without delays. The mobile app provides an overview of assigned tasks and due dates, enabling users to review detailed information on each request and make informed decisions—approve, reject, request changes, or delegate—without switching context. This feature will help ensure compliance and budget alignment while maintaining a smooth approval process.

Copilot features

Dynamics 365 Supply Chain Management customers can access the Copilot in the Microsoft Supply Chain Center. It’ll proactively flag external issues, such as weather, financials, and geography that might impact key supply chain processes. Predictive insights then surface impacted orders across materials, inventory, carrier, distribution networks, and more. Supply chain planners can then automatically draft an email generated by Dynamics 365 Copilot to alert impacted partners and mitigate potential disruptions before they happen.

Additionally, in-app help functionality provides users with immediate, contextual assistance from within the application and user processes:

Draft precise responses to user queries: Copilot utilizes the extensive repository of public documentation on Dynamics 365 Supply Chain Management features, and it bases generative AI on the product documentation to craft precise responses to user queries.

Context aware guidance: Users can pose questions related to their current context, and then Copilot provides tailored and specific guidance.

There also are on-hand inventory insights to help users make informed inventory decisions, such as for order promising:

Query on-hand inventory: Provides the ability for users to use natural language to ask about inventory stock levels and availability, just as easily as when chatting with a colleague. For example, you can simply enter Find all the 18-inch tires in my store without needing to remember exact specifications, IDs, or navigation paths.

Inquire Inventory: Provides a guided conversational experience to quickly identify the best available products for order inquiries without users having to leaving the Microsoft 365 work context. Sales managers focus on communicating with customers and increasing sales. Having product inventory levels handy from Microsoft 365 helps sales managers please customers and close deals faster.

Enable third-party apps or websites to query on-hand inventory: Natural-language search application programming interfaces (APIs) for Inventory Visibility can integrate with third-party eCommerce websites or apps. Customers can use them to build a chat feature for third-party apps or websites that helps customers find products, and review availability and alternatives.

Copilot helps procurement specialists make better purchasing decisions in procure-to-pay processes:

- Manage purchasing decisions with Copilot: Copilot support for procurement is an advanced tool that empowers users to efficiently manage and assess changes to purchase orders on a large scale. By classifying changes by impact and associated risk, it greatly enhances procurement decision-making. With Copilot, users can swiftly identify high-impact or low-impact alterations and analyze downstream impact, thereby enabling prompt actions to mitigate potential risks.