Outbound setup

Output orders serve as a connection point between sales order lines, transfer order lines, and the outbound picking procedures that picking lists facilitate. When you generate picking lists from sales orders or transfer orders, the system automatically generates output orders and shipments. Each picking list corresponds to a single shipment. Then, you can process the shipment through the transfer order shipment or the sales order packing slip.

Picking route status for sales and transfer orders

A picking route status is an indicator that reflects the current state of a picking route within the warehouse management process. To set up the picking route status for sales orders, go to Accounts receivable > Setup > Accounts receivable parameters. Select the Updates tab and then expand the Picking list FastTab. Depending on your organization's business processes, you can set the Picking route status as Completed or Activated. If you select Completed, the picking process automatically occurs during the process of generating picking lists. If you set the field as Activated, then you must update the picking list lines manually.

To set up the picking route status for transfer orders, go to Inventory management > Setup > Inventory and warehouse management parameters. Select the Transfer orders tab. Under the Picking route status field, select Activated or Completed.

End output inventory orders

When your warehouse worker decreases the quantities on the picking list, the system deducts the corresponding quantities in the inventory order from the shipment. To turn on this feature, go to Inventory management > Setup > Inventory and warehouse management parameters and select the General tab. Set the End output inventory order toggle to Yes so that, when a warehouse worker revises the picking list, the system reports the remaining quantities back to the order. If the End output inventory order option is set to No, the system keeps the remaining quantities as an open output order quantity. Therefore, you must add the remaining quantities to a new picking list as part of the Open output orders functionality.

Reduce quantity

When your warehouse clerk posts the picking list, they can use the Reduce quantity functionality on the post picking list page. When they set the Reduce quantity option to Yes, the setting works together with the Reservation setting that initiates the reservation process with the release to warehouse.

Example of an outbound process for a sales order

In this example, a sales order contains two items. During picking list generation, you select the Reduce quantity parameter.

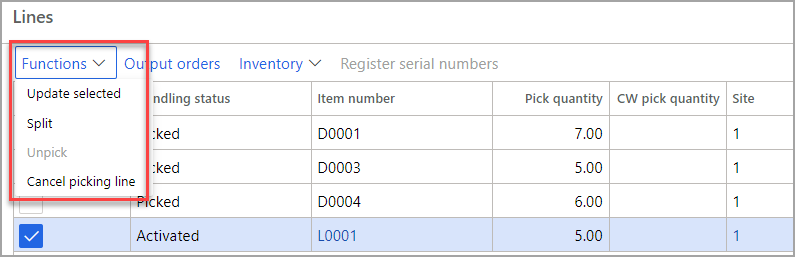

As a result, you release and create picking lines only for available inventory. You must report the picking by means of a registration process for picking lists (Picking route status = Activated).

You plan to reserve the inventory that isn't already reserved during picking list generation. You can remove the unavailable inventory from the sales order, or you can release it to the warehouse for outbound processing later when inventory is available for picking.

After you pick all picking lines on the Picking list registration page, the system completes the associated shipment. Then, you can initialize the process for sales order packing slips based on the picked inventory.