Production input location

Consumption is the process that deducts material from on-hand inventory and sets the value of the consumed materials to Work in progress (WIP) for production orders and batch orders. Raw materials are usually consumed from a location that is configured for the process that consumes the material. This location is known as the production input location.

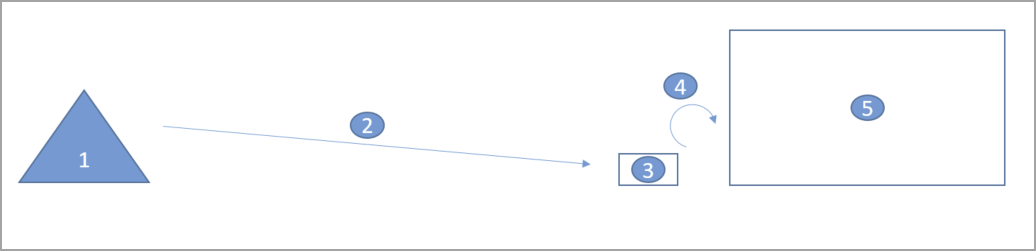

Before material consumption, materials are moved to the input location. The following image shows the process.

- Material warehouse

- Raw material picking

- Production input location

- Raw material consumption

- Production process

To support an efficient process for raw material picking in production, you can split warehouse work for raw material picking for each route operation.

On the resource groups, and the relation between the resource group and the resource, you can set up a production input location to be used in warehouse work. This feature helps secure a more efficient picking process for production and batch orders because the warehouse work will direct the warehouse worker to the exact locations where the material is consumed. This process is useful in a "bulk/pack production" scenario.

Example

In this scenario, one operation exists for making the bulk material and one operation exists for bottling and packing. These two operations are consuming materials, but the process will be carried out in different physical locations, potentially different buildings. Splitting the work for each operation will, in this case, secure a process where the warehouse worker is directed, by warehouse work, to deliver the picked materials to the exact locations where the materials are consumed.

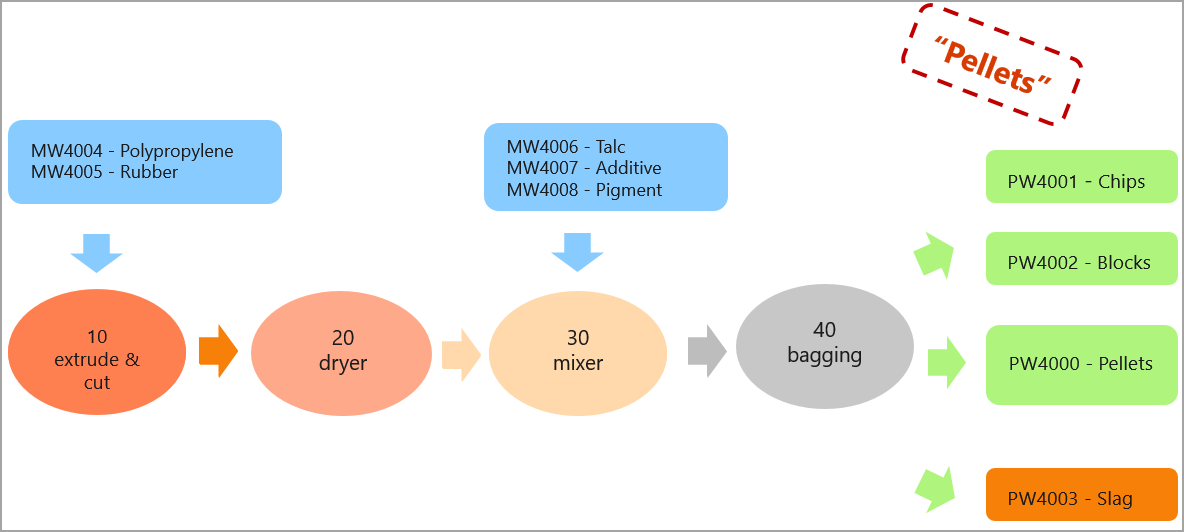

The following image shows pellets production from the USPI Company, which is available in the standard sample data available in Supply Chain Management that is installed by using Lifecycle Services.

The following information provides an overview of the items in the image:

The following information provides an overview of the items in the image:

- The item numbers for the ingredients (or raw materials) are prefixed with MW.

- The four end items are prefixed with PW:

- PW4000 - Pellets is the formula item.

- PW4001 - Chips and PW4002 - Blocks are coproducts.

- PW4003 - Slag is a by-product.

As the image shows, ingredients from the pellets production are consumed at two different operations. The following sections explain how work is now split for each operation when you release a batch order for the pellets formula.

First, create a batch order for pellets and perform the steps Estimate, Schedule, and Release. In the Release step, warehouse work is created and two warehouse work items are created.

The first work item is for allocating materials to the extruder operation, which is the first operation in the route. The materials are allocated to the production input location EXT.

The second work item is for allocating materials to the mixer operation. The materials are allocated to a production input location MIX.

Enable the production input location

This section takes a closer look at how to enable the production input location.

First, set up the production input locations that will be applicable for the route operations. The pellets formula has a production route with four operations.

The first operation, PPExtCut, is consuming MW4004 - Polypropylene and MW4005 - Rubber. An applicable production input location for this operation is found through the Resource requirements for the operation. In the Resource requirements section of the route, you can set up criteria for finding an applicable resource or resource group during scheduling.

The input location can be specified on the resource group but also on the relation between the resource group and the resource.

If no input locations can be found from the resource groups or resource group relations, then a default production input location is used as a fallback location. This default input location is set up on the warehouse.

After setting up the input locations, you need to specify which operations are consuming which materials. You can set up this mapping on the material lines by using the Oper. No field. If no operation is specified on the material line, then you can find the production input location from the resource group or resource group relation, which is applicable for the first operation in the production route. If no applicable input locations can be found, then the default input location for the warehouse is used.

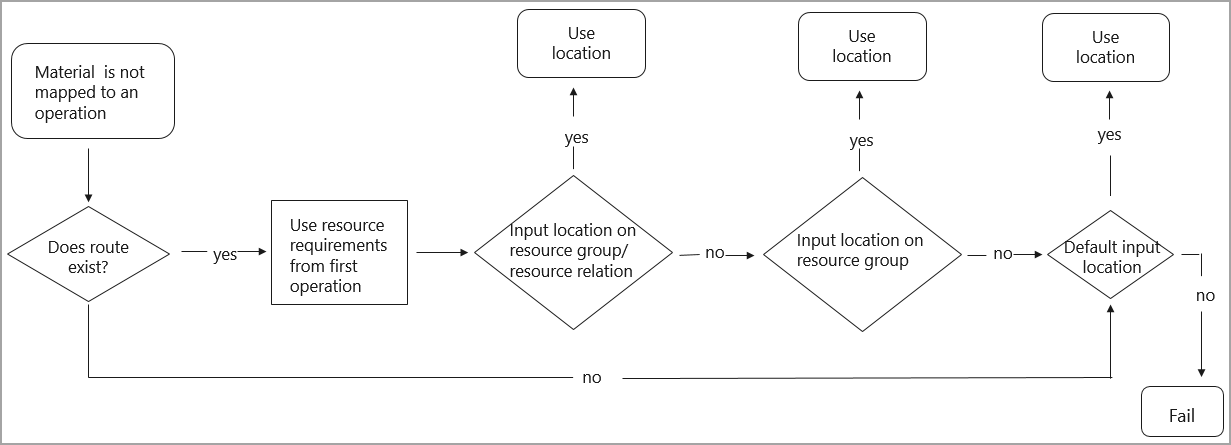

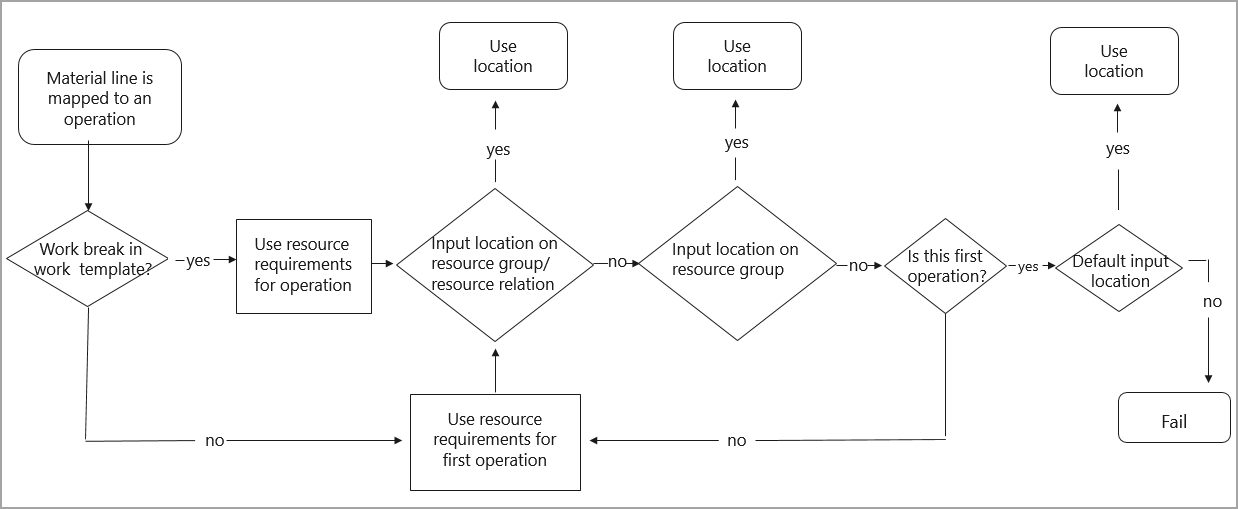

The default hierarchy is shown in the following diagrams.

The first diagram shows the rules that apply for finding the production input location for a material line that is mapped to the first route operation or does not have a defined location.

The second diagram shows the rules that apply for finding the production input location for a material line that is not mapped to the first operation but to one of the following operations in the production route.

When a new work template for raw material picking is created, a work break is automatically inserted. This work break is configured by Supply Chain Management to group work for each route operation. You can remove the work break and, in that case, only one work item will be generated when you are releasing to the warehouse from production. In that case, the input location that is found from the first operation in the route will be used as production input location, and if none are found on the route, the default input location is set up for the warehouse.