Setting up the production output location

This new functionality is available with KB 2995954 and will be included in Microsoft Dynamics AX2012 R3 CU8. To find the HF you can use LCS Issue Search.

What's new?

To support an efficient process for putting away produced products, it is now possible to define an output location specific for a production or a batch order. This will enable the warehouse worker to exactly know where to go, to pick up the goods for put away.

The illustrations below shows the difference between the R3 and the CU8 implementation. The first illustration shows the R3 implementation where it was only possible to define one output location per warehouse:

The second illustration shows the CU8 implementation. In this implementation it is possible to set up an output location per production or batch order. This will give the warehouse worker a better overview of where to pick the finished products for final put away

This blog will explain how this new capability is enabled by using the official demo data released for Microsoft Dynamics AX 2012 R3 CU8 Virtual Machine (VM).

In the company USPI there is a formula for making Pellets. This formula will be used for showing how this feature is enabled and used.

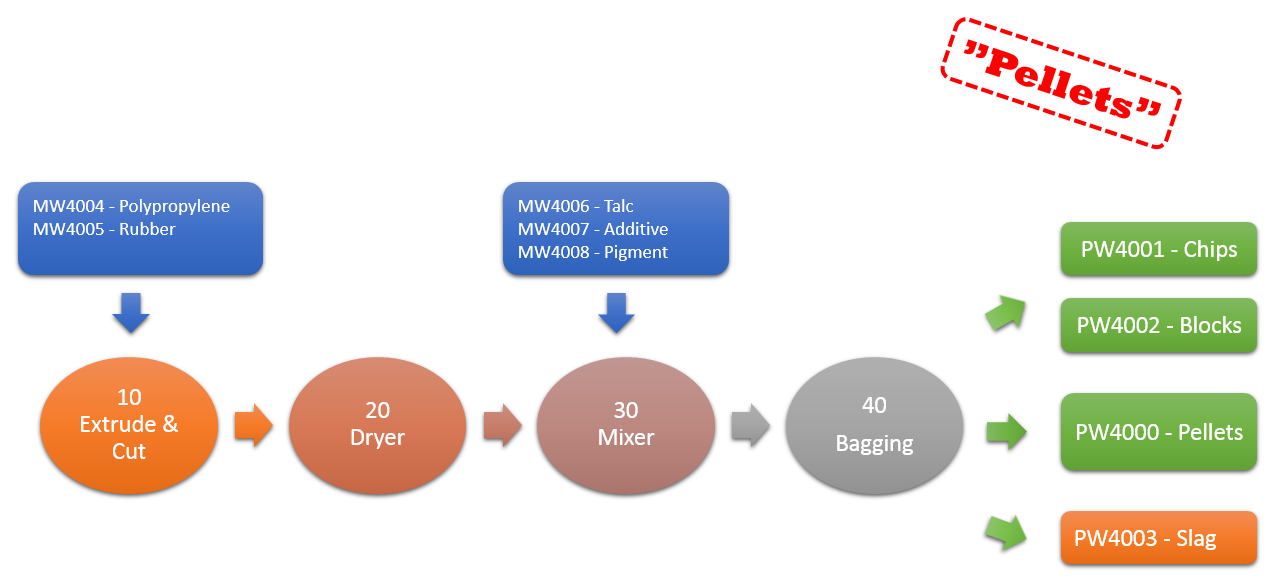

The illustration below shows the Pellets production:

The item numbers for the ingredients (or raw materials) as MW4004 - Polypropylene and MW4005 - Rubber are pre-fixed with MW and the four end items are pre-fixed with PW. PW4000 - Pellets is the formula item, and PW4001 – Chips and PW4002 - Blocks are co-products. PW4003 - Slag is a by-product

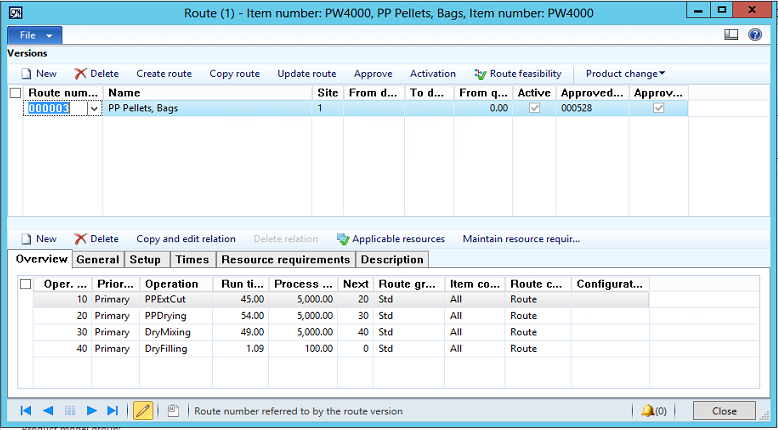

Let us take a closer look how to enable this feature. First we need to set up the production output location. Looking at the route for the Pellets formula operation 40 DryFilling is the last operation:

An applicable output location for this operation is found through the Resource requirements for the operation. In the Resource requirements, criteria for finding an applicable resource or resource group during scheduling, is set up:

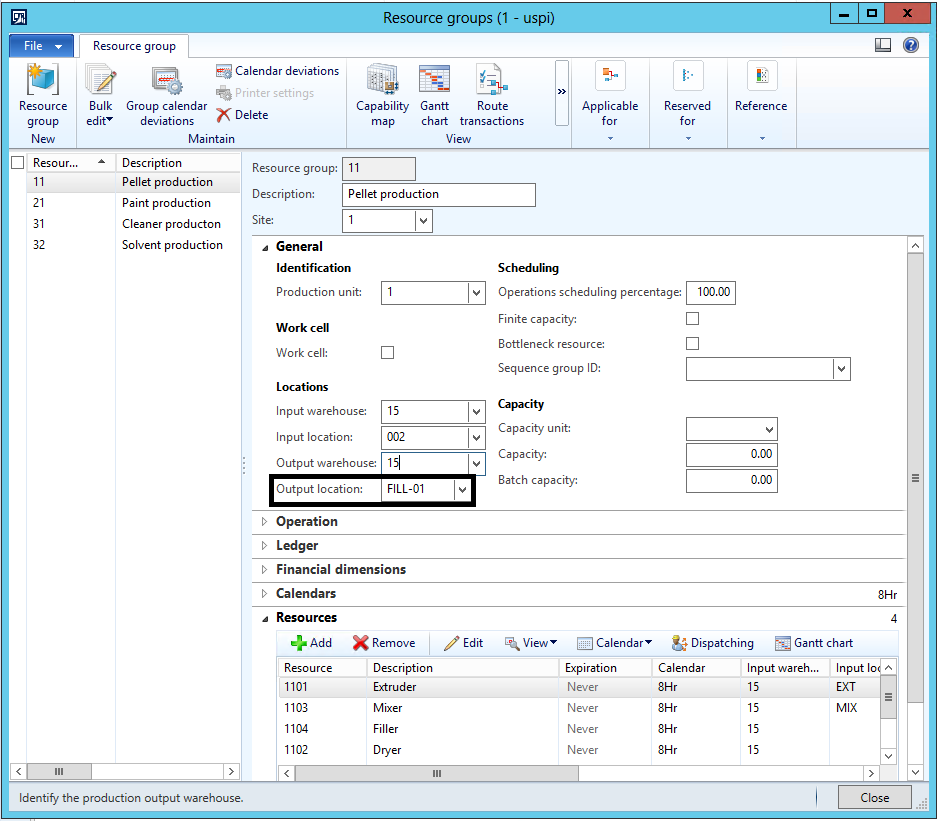

The output location is specified on the resource group, as it can be seen in the illustration below:

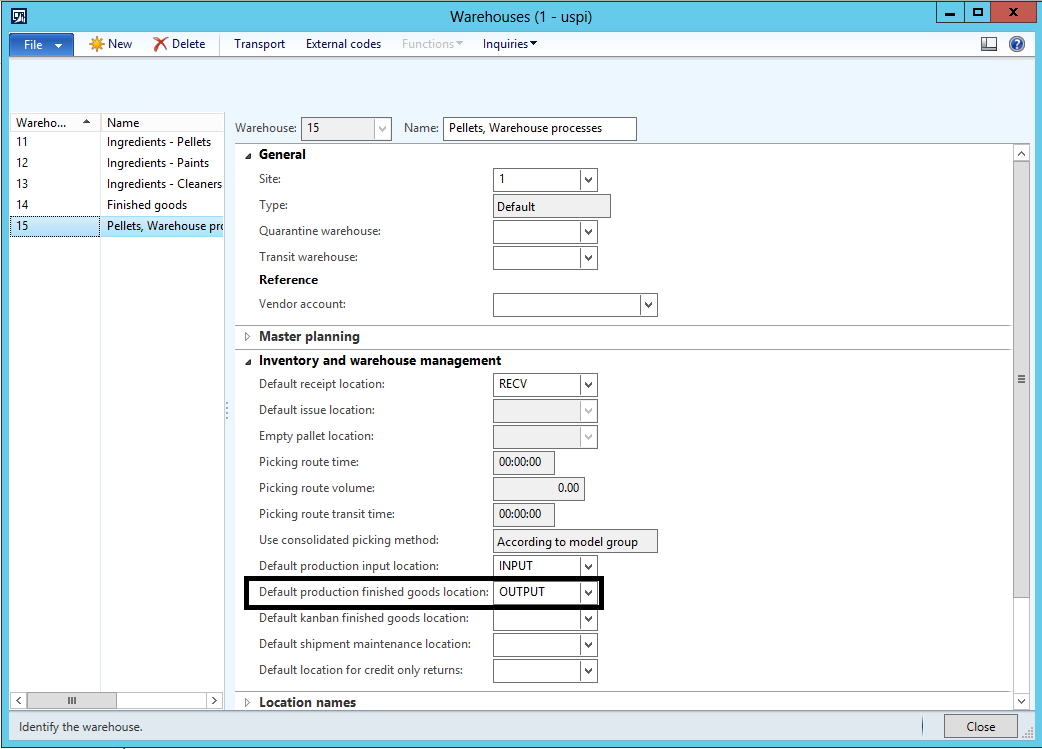

In case no output location is defined on the resource group, then a default production output location is used as a fallback location. This default output location is set up on the warehouse:

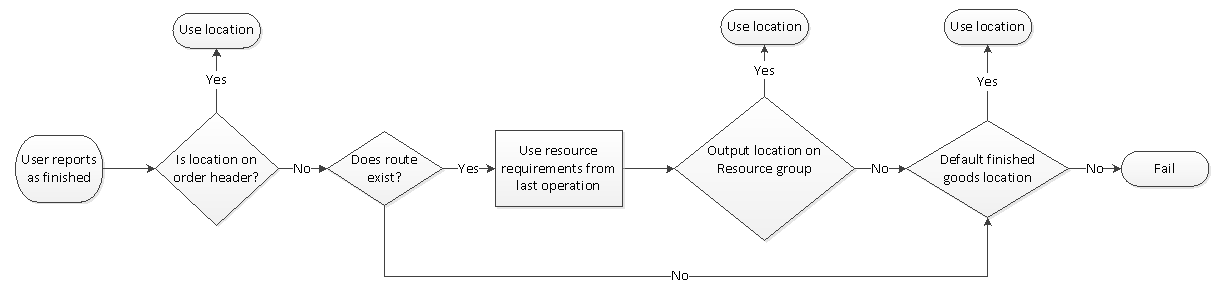

In the diagram below the defaulting hierarchy is shown. The diagram shows the rule that applies for finding the production output location when reporting as finished for a production or batch order:

Example

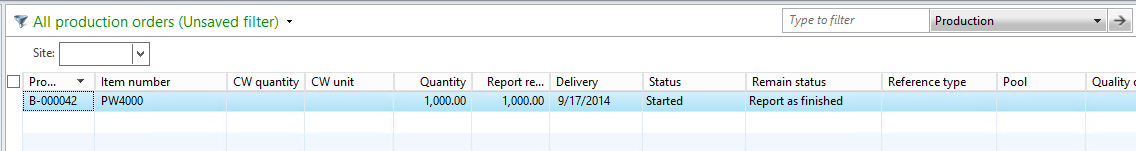

To see how this works, let us report as finished a quantity of the formula item PW4000 – Pellets. The batch order is in status Started and is ready to be reported as finished:

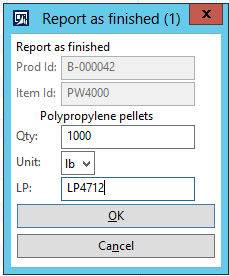

Reporting as finished is done from the mobile device:

Batch order number, Item number, quantity and license plate is entered:

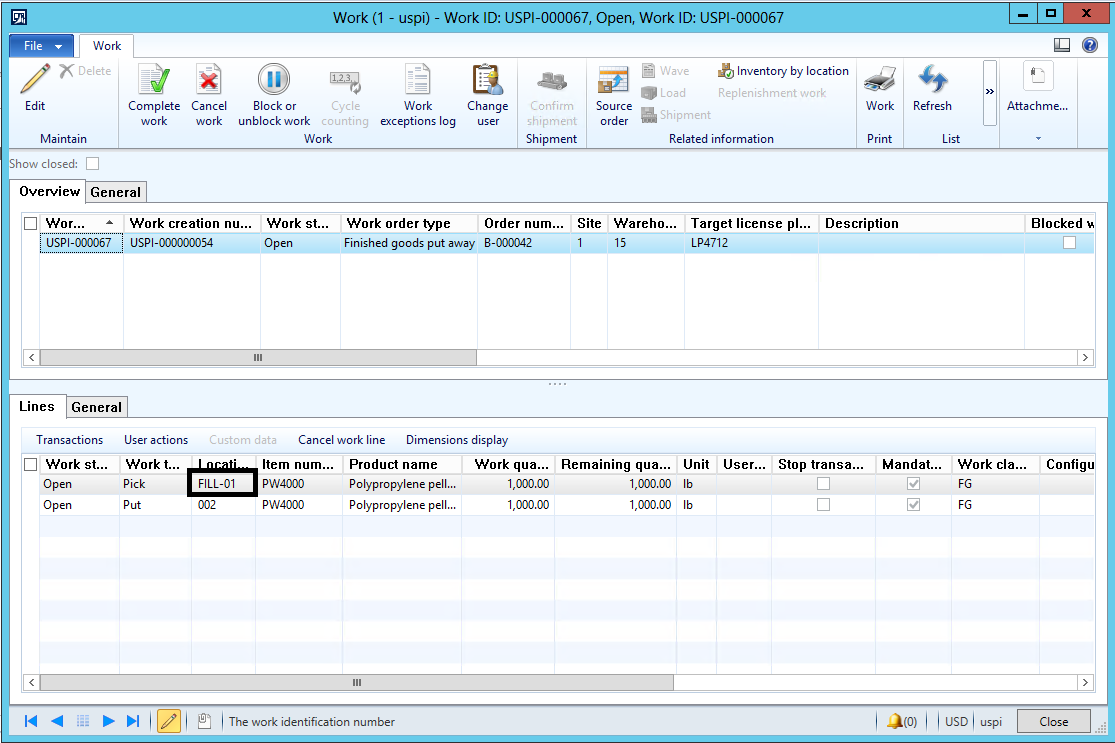

And the process is completed and put away work is generated:

Taking a closer look at the put away work, the pick location for this work is FILL-01. This location is the output location that was set up on the resource group that is applicable for the last operation DryFilling

Let us try to remove the output location from the resource group and then report as finished one of the co-products from the batch order

We report as finished a co-product PW4002 – Blocks and put away work is generated

The put away work will in this case have the default output location OUTPUT. This location is the fallback location set up in the warehouse

The defaulting of the output location is enabled for all the places where the reporting as finished process can be performed. This includes

- Using the report as finished function from the batch order

- Using the report as finished journal

- Reporting as finished from the job or route card journal. This is possible when user reports on last operation and marks the field Report as finished on the journal line

- Report as finished from list page Current operations. This is possible when reporting as finished the last operation

- Reporting as finished from the Job registration form in the manufacturing execution module (MES). This is possible when the user reports as finished the last operation

Summary

In CU8 it is now possible to set up an output location for the last operation in a production route. This supports a more efficient process for putting away produced products from the shop floor to the warehouse. The output location is set up on the resource group that is applicable for the route operation. A fallback output location set up on the warehouse is used in case no output location is defined on the resource group. Using the output location defined for the last operation in the production route is applicable for all the places where the report as finished process can be performed.

Comments

Anonymous

May 28, 2015

Is this part of CU8? I do not see the new fields against a resource.Anonymous

July 27, 2015

Hi, I am trying to perform report as finished from mobile device as per above setup using default FG location. I am getting error that inventory dimension location is not available on production order. When, I try to maintain it, since location is mandatorily license plate controlled, I have to define the license plate also which is not generating automatically on production order form. Also, I want to understand if report as finished can be done without using production/batch order with BOM journal. Please help me.